Check the "bay. They had several of the above for $30-40 buy it now.

I found a few more on eBay looking for the square d one in the 20.00 range. I don't want really cheap ones these get a lot of use in my shop.

Steve knight

cnc routing

ebay has them too if you want a USA made one. $30-$40.

http://www.ebay.com/sch/i.html?_from...ation&_sacat=0

got these about all the money I had left

http://www.ebay.com/itm/110994144693...%3AMEBIDX%3AIT

Steve knight

cnc routing

got one set of buttons working but when I tried the second with the same wire it won't work. After thinking the stat works but not stop but that makes sense since the stop always stays closed since one button will always be closed. is it possible to run two switches? separate wires?

Steve knight

cnc routing

You need to run three wires to each start-stop pair. The start switches are wired in parallel, the stop switches in series.

Beranek's Law:

It has been remarked that if one selects his own components, builds his own enclosure, and is convinced he has made a wise choice of design, then his own loudspeaker sounds better to him than does anyone else's loudspeaker. In this case, the frequency response of the loudspeaker seems to play only a minor part in forming a person's opinion.

L.L. Beranek, Acoustics (McGraw-Hill, New York, 1954), p.208.

I am missing something. right now I have the starts in series and they work but not the stop. but I can't see how to have both stops open when one is pushed. I bet it is simple but I am not getting it.

Steve knight

cnc routing

To add a switch to Don's diagram:

Connect the black wires from both switches together and to terminal 53

Disconnect the green wire coming from the original switch from terminal 95 and connect it to the white wire coming from the new switch

Connect the green wire coming from the new switch to terminal 95

That's for a star configuration. If you're doing a daisy chain then instead of removing the old green from terminal 95 disconnect it from the old switch and splice it to the new green wire. Connect the new white wire to the old switch where you removed the old green wire. Connect the black wires together and to the old switch.

Beranek's Law:

It has been remarked that if one selects his own components, builds his own enclosure, and is convinced he has made a wise choice of design, then his own loudspeaker sounds better to him than does anyone else's loudspeaker. In this case, the frequency response of the loudspeaker seems to play only a minor part in forming a person's opinion.

L.L. Beranek, Acoustics (McGraw-Hill, New York, 1954), p.208.

A bit late, and i'm not familiar with the sort of installation being discussed - but one option to run a say 4KW 230V 3 phase motor here in single phase land is to hook it up to a single to three phase VFD. Then use the control terminals and functions provided to start and stop it by wiring a switch or even using a wireless remote. (easy to wire a stock $50 garage door closing set up to do the job) A three phase model could also be used if it suited better.

You get a programmable soft start, and also speed control, braking, reversing etc if required. The soft start is incredibly effective at holding down the start current, mine draws only about 125% of the steadt=y state run amps on start up. Speed control can be very useful on a dust system, sometimes a small shift in RPM can have big effects in terms of noise level for example.

The Yaskawa on my dust system has been rock solid reliable for four years of intermittent use now.

a vfd would be nice but it is an expensive option. though the one on my spindle on my cnc router is great it is overkill for a vac system. Plus this vacuum is not big enough to need a reduction in rpm.

Steve knight

cnc routing

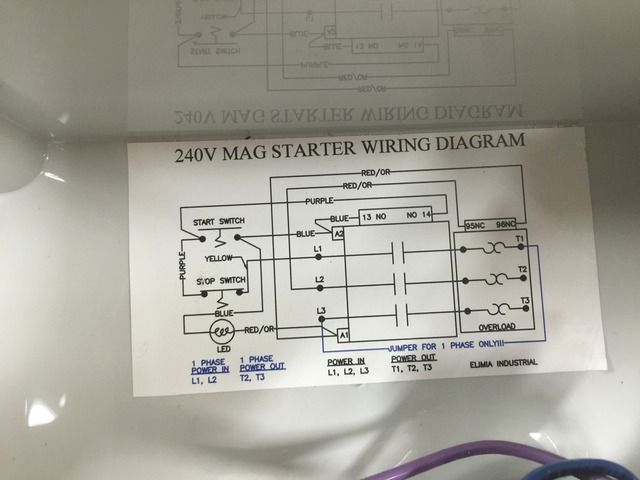

my blower died and got replaced with two a bit smaller so I needed smaller starters. can I get home help on wiring the remote switch? I have a pretty good idea just doing wires to the switches but I want to make sure. there is a led light in there can someone tell me the voltage? I want to run a LED at the switch.

Steve knight

cnc routing

I was going to suggest a VFD also, since hooking up a remote to most of them is simple.

If you already have a mag switch, then I wouldn't consider it (unless you can use that mag switch on another machine, or sell it.)

You say you have no need to slow the motor down, but with a VFD (and a decent, high efficiency motor) you could experiment with speeding it UP. Finding just the right speed for an impeller is probably a "try it and see" thing.

Also, a VFD offers soft-start, which is definitely a good thing on a blower system. Over time, it could save your motor from premature death.

Last edited by Allan Speers; 07-12-2015 at 9:51 PM.

I just bought two new starters as I traded the bad blower for two slightly smaller ones. but the starters have a slow start on them already. my first blower ran buy t was noisy and ran hot I did to know about who blowers worked so thought it was normal. but then it died while I was cutting some phenolic that smelled like burning motor so I could not smell it. the company replace but they did not have one in stock so I got a slightly smaller one and another so I could choose one or two depending on my needs. I have already spent too much money on this. 540 for the other motor 380 for two new starters wire the right size vacuum relive valve for them both. I have one switch hooked up I just need to put the wires on one of the starters and wire in the second starter.

Steve knight

cnc routing