Let's try this s again. I keep deleting my response.

Brian, I thought long and hard about a planing bench, but I would still need a bench and I don't want to keep knocking something down and setting it up. The shop is bigger than I may have suggested. It is roughly 12 x 17. I am moving stuff around and it will fit fine with 3' between me and the tool cabinet, and close to that on the pattern vise end. The other side has tons of room but has to serve as a pass through to the exit door on one end, and entrance to the downstairs kitchen (which has been commandeered as a sharpening area) on the other end. The air compressor will move into the storage area and that tall cabinet moves out of the way as well. I am moving stuff around so the shop is a wreck. The stuff piled on the bench is waiting for me to finish moving stuff.

Attachment 319747Attachment 319748

Kent- Surfboards and replacing these 8.5' doors with mahogany ones are on the list.

Attachment 319749

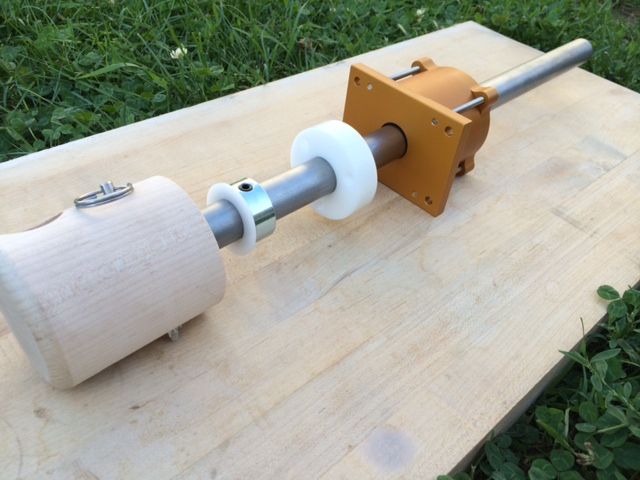

Joe- Benchcrafted and Hovarter are the only two leg vises I am considering.

Reply With Quote

Reply With Quote