I find most store bought dust collectors seem to be either expensive, or under powered, or too small an impeller, or both, and to boot often an ineffective impeller in aluminum with straight vanes.

Since I am too cheap and poor to splurge on an expensive DC that would meet my own standards I decided to build my own after seeing people like Matthias Wandel and Marius Hornberger and others building their own homemade dust collectors.

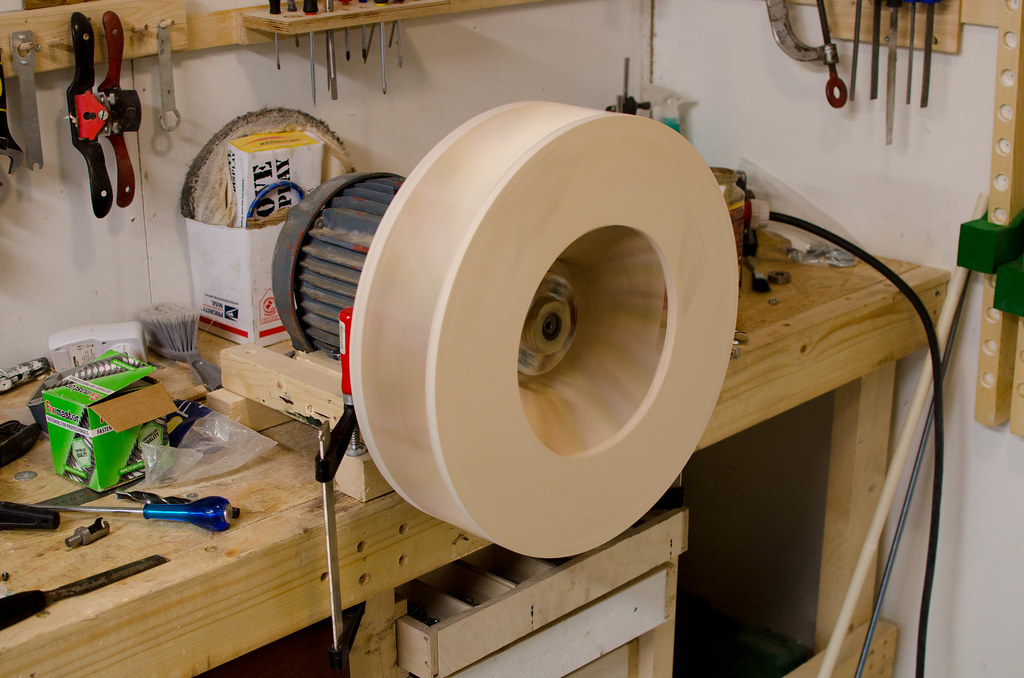

Here's what I got so far, an 18" diameter impeller, highly curved backwards vanes with a top plate. Top plate increases performance and strength of the design.

It's been balanced and tested, it sounds like a jet engine. It's driven by a 5.3HP 2880RPM 3-phase motor I picked up for 25 bucks. I had a 10 meter extension cored wired to my onoff switch and stood outside the garage when running it. When it's done it will be put in another smaller storage room and remotely started.

Spinning down

This isn't a material handling impeller, that's the trade-off for a more efficient design. I will build a separator and also add a manifold with multiple cylindrical HEPA filters before the impeller, like what you can get for shop vacs. So it only sees clean air and then returns that to my shop. In the summer I might just eject the air outside.

I am using multiple filters in my design because the outlet hole for a single filter is going to be too small. One could also use a big rectangular filter, but I am not sure if those are more or less effective. I can buy the cylindrical ones locally quite cheaply.

I think that if I didn't want to return the air I wouldn't use any filters, just separate and have like chicken wire to protect the impeller from big pieces. But I believe I want to, I was told an impeller this size only needs a few seconds to empty all the air in a small shop, that's no fun if it's -20C outside.

Reply With Quote

Reply With Quote