I have volunteered to make a gateway entrance for a 50' by 50' pollinator/butterfly garden at Millbrook Marsh Nature Center, a local wetlands education and conservation center.

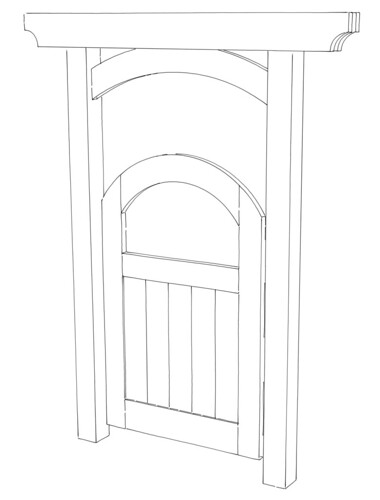

The gate will be about 3' wide and 6' tall. Here is a rough drawing of my current plan. For now, Iíd appreciate feedback on the gate itself. I will post separately on the gateway (posts and crossbar) later.

I would appreciate your comments on the appearance and practicality of this design. Some specific points are outlined below.

Finish

Given the location, I think that regular maintenance of any finish is not likely. So I am inclined to leave it unfinished and allow it to weather.

Wood Choice

This gate needs to be able to take some abuse because it will see quite a bit of traffic, including lots of kids.

The wood needs to resist decay well.

The wood has to be available at a reasonable cost in central Pennsylvania.

Iím leaning toward white oak, although this will be heavy.

Construction

All boards will be the same thickness, about 1 5/8 inches.

The three rails will be fastened to the stiles by mortise and tenon. I will use Titebond III. Do I need to worry about vertical (cross-grain) expansion of the rails? The cross-grain dimensions of the rails vary, but are in the neighborhood of 8". Iím not sure how to apply the usual calculations for wood movement in an outdoor setting.

For example, should I glue the tenons but keep glue off of the shoulders?

The boards making up the panel for the lower portion will be joined together and to the frame using unglued tongue and groove joints. There will be appropriate spacing to allow for wood movement.

The upper portion will be open. Something decorative may be suspended in this opening; for example, a stylized butterfly.

Reply With Quote

Reply With Quote