Hi.

when picking boards, I'm curious as to others methods...

I normally look at end grain and seek vertical, or as close to, as possible.

It was suggested to also consider edge, or long grain...

what do you look for and in what order?

Hi.

when picking boards, I'm curious as to others methods...

I normally look at end grain and seek vertical, or as close to, as possible.

It was suggested to also consider edge, or long grain...

what do you look for and in what order?

Depends.

I sometimes chose quartersawn for stability. For chairs and structural parts, I always select this way.

For panels on show pieces, I select for pattern first.

In general I try to select out the pith and take pains to make sure my wood is dry for all things.

Vertical end grain might be a little ambiguous. If I am looking at 2X3 (just an example) Sometimes I would look for grain parallel to the long dimension. Other times I might want it running in the short dimension.I normally look at end grain and seek vertical, or as close to, as possible.

It was suggested to also consider edge, or long grain...

what do you look for and in what order?

As far as edge grain is concerned, I look at it to see how it will act on my bench as a plane is being used. It is preferred to have grain run out going upward in the direction of the plane.

If I am going to be cutting some molding, I will also look for the face grain to be running toward the side that will be guiding the fence.

Most of the time I am using the most economical of woods. First I look for knots and other problems to be avoided. Then I look for consistent grain. My only look at the end grain is usually to make sure there aren't cracks, checks or other potential problems.

jtk

"A pessimist sees the difficulty in every opportunity; an optimist sees the opportunity in every difficulty."

- Sir Winston Churchill (1874-1965)

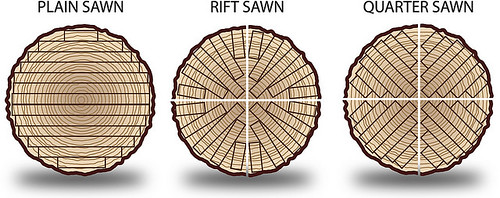

I don't know if "vertical end grain" is an official term. I've always thought of it as end grain running vertically across the width of a board. Rift sawn boards cut on the radial plain will have this. Other sawing methods will produce occasional/random vertical grain boards. Choosing a vertical grained board from lumber that was say plain sawn will get you a rift sawn board at a lower price.

Last edited by robert dankert; 11-21-2015 at 1:48 PM. Reason: My error, reason explained in post #8

Robert ^, he's talking about QS wood.

To the OP:

Quarter sawn is the most stable and less likely to move so, its great, especially for for legs and door stiles.

Usually on a show face like a raised panel or top, figured grain patterns revealed in rift or flat sawn wood can be most attractive, but also, QS can give the most beautiful figure due to ray flaking, such as tiger maple and oak.

Legs and other single pieces visible from more than one side often look best when rift sawn (end grain approx 45 deg) because the grain is similarly spaced on all faces.

C

As I understand it, rift sawn boards have the vertical end grain orientation. Quarter sawn will yield most of the boards with angled grain.

I made that same mistake in my post to the OP when I associated quarter sawn and vertical grain. I made the statement that methods other than rift or quarter sawn would occasionally produce a quarter sawn board. This is true and you might also find a rift sawn board.

Robert, the definition of rift sawn on your drawing is incorrect according to current industry practices. Pictured below is a correct diagram obtained from the current edition of "Architectural Woodwork Standards":

AWI rift and quarter lumber diagramv2.jpg

The best that I have been able to determine is that earliest version of the drawing above that you shared of rift sawn lumber dates back to a mistake that was made by a manuscript editor of a FPL publication back in the 1930's. FPL corrected the mistake in subsequent versions of the document, but numerous copies of the document had already been released and the misinformation exists to this day.

All: There are several different industry recognized organizations that provide information about quarter and rift sawn lumber. These include the USDA Forestry Products Lab (FPL), the National Hardwood Lumber Association (NHLA), the National Hardwood Flooring Manufacturers Association (NHFMA), and the Architectural Woodworking Institute (AWI).

All of these organizations agree that quartersawn lumber is determined by the angle that the annular growth rings intersect the face of the board. Unfortunately, they don't all agree on exactly what that angle is. Some define it as between 60 - 90 degrees, others define it as between 75 - 90 degrees, and still others define it as 45 - 90 degrees.

In Bruce Hoadley's book "Understanding Wood", he defines quartersawn lumber as that where the growth rings form angles of anywhere from 45 degrees to 90 degrees with the surface, with "rift grain" indicating surfaces intermediate between 45 degrees to 90 degrees. Hoadley also refers to rift sawn lumber as "bastard grain" too. Unfortunately, Hoadley does not provide references to any FLP, NHLA or AWI standards in his book.

The current industry recognized definition of quarter and rift sawn lumber recognized by architects and professional cabinet shops nationwide is published by the AWI. AWI defines quartersawn lumber as having annual growth ring orientation between 60 - 90 degrees relative to the face of the board. AWI defines rift sawn lumber as measured by annular growth ring orientation between 30 - 60 degrees to the face of the board, with 45 degrees being "optimum" (page 449, Appendix B, section 3 Lumber of the 2009 1st edition of Architectural Woodwork Standards with drawing from same posted above).

Pretty much the entire woodworking manufacturers industry adheres to the AWI standard regarding rift and quarter sawn lumber.

Plain sawn lumber is also called "flat sawn".

Trevor, there are several different milling techniques that produce quartersawn lumber. Perfectly quartersawn lumber requires that the pith of the log be centered in two planes when milling, in order to achieve an edge grain that has minimal if any slope of grain relative to the face of the board. When you look at a quartersawn oak board that has high ray fleck on one end of the board and much lower fleck on the opposite end, this is the result of either a crook in the log or the fact that the log was only centered in one plane when milling. Typically higher grade of quartersawn boards will have minimal slope of grain when viewed from the edge.

I think that Prashun's description of how he selects lumber is well presented. Although I love quartersawn lumber, in many instances non quartersawn grain boards can be used for extraordinary effect by advanced woodworkers. It all depends upon your project and the end presentation that you desire.

Last edited by Scott T Smith; 11-21-2015 at 8:42 PM.

I always associated true quarter sawn as being growth rings perpendicular to the large face of the board, and rift sawn as being closer to 45 degrees like Scott refers to above.

For furniture, I largely do what Prashun suggests but also try and select boards for color and to minimize runout.

For acoustic guitars, quarter sawn wood is often used for its stability, but also because it is noticeably stiffer than rift or flat sawn when the boards start to get very thin.

Thank you, it most certainly does not match. The AWS reference was very helpful.

The internet is loaded with versions of that picture and subsequent descriptions of QS with angled grain and rift with vertical (including wikipedia). The Hardwood Distributor's Association defines rift sawn like AWS: ". . .annular rings of a rift sawn board are about 30-60 degrees to the face of the board . . .". They show a picture of a rift sawn board (angled grain) but then insert a drawing like the one I posted to illustrate "A typical cut pattern for cutting rift sawn lumber".

One FPL, General Technical Report FPL–GTR–190, states: ". . . lumber with rings at angles of 45° to 90° to the wide surface is called quartersawn" (no mention in this paper of rift sawn). I couldn't find definitions at NHLA or NHFMA websites.

It's a confusing subject to say the least.

+1