1 Feb 2016

Good Morning Everyone,

Trying to get a head start on posting since I'm off work and have a doctor's appt to get to. Been wrestling with vehicle troubles and I dislike vehicle troubles. I never knew that I'd be wrestling with vehicle issues at my age. My 2 boys, still living at home, are always needing transportation for something and I need transportation to get to/from work and etc. My old truck is down for the count because my gracious SIL is fixing it for me. I bought parts and have more parts on the way. I'm going to pay him for the work but I just strongly dislike vehicle troubles.

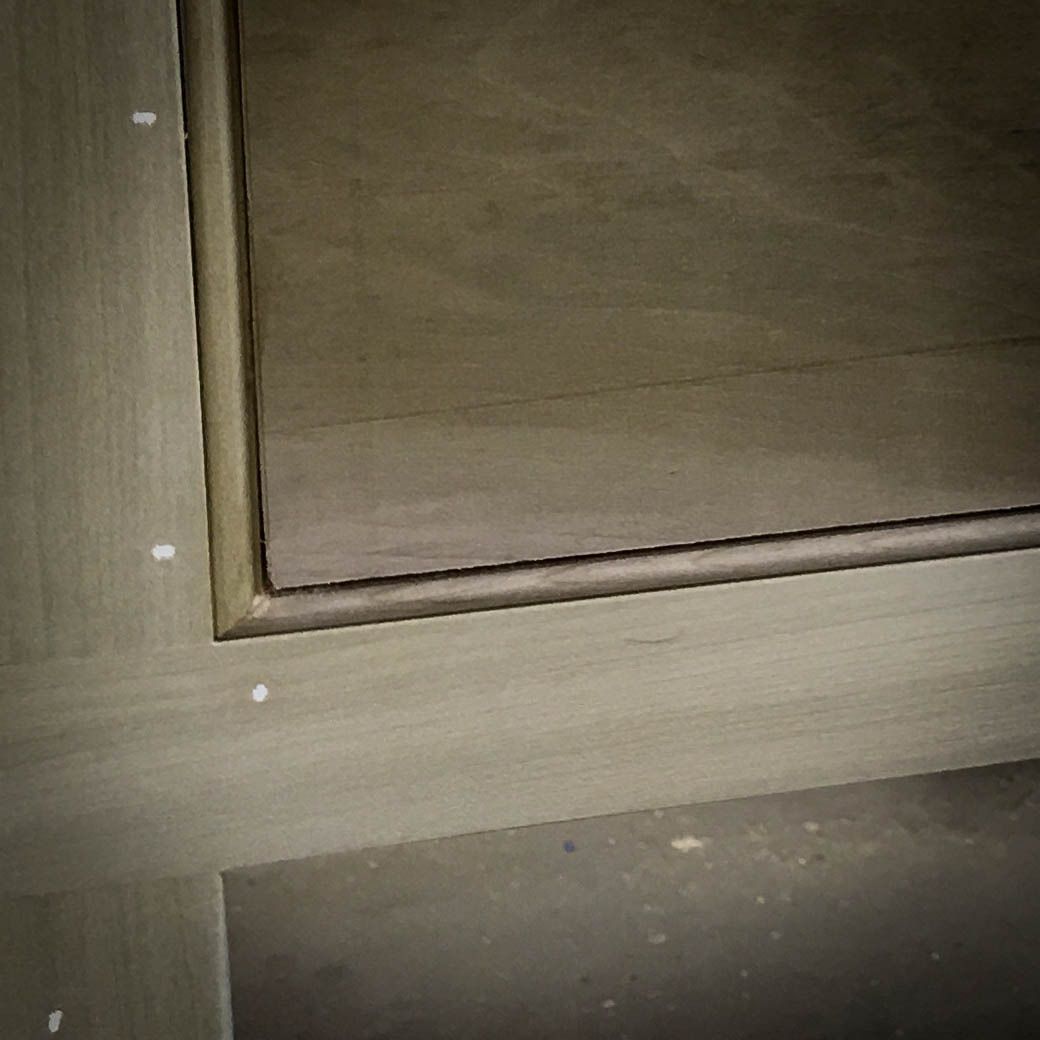

Making some room in my shop so I can get started working on things once more. I just need time to get things under control. The LOML and I are still working out at least 3 times each week at the gym we joined and in 5 weeks time, I've lost 10 pounds in weight and 2 inches from around my mid-section. I'm feeling better and really enjoying the workout and the weight loss.

That's it for me, so what did YOU do this past weekend?

Best of weeks to you all.

Reply With Quote

Reply With Quote