8 Feb 2016

Good Morning Everyone,

I've had a little time to play the guitar I just finished building and found that I got one of the grooves for one string just a tad too deep and the string has a dead sound to it. Now it's time to figure out how to fix that little issue and get back to playing it again. I really like how well it plays and how well it sounds. The Telecaster building is now under way and I hope that this guitar plays as well as the first one I just finished. This has really been fun.

Getting back to oncall duty and my hope is that it is quiet enough to where I will get some sleep during this week.

That's all for me, so what did YOU do this past weekend?

Best of weeks to you all.

Reply With Quote

Reply With Quote

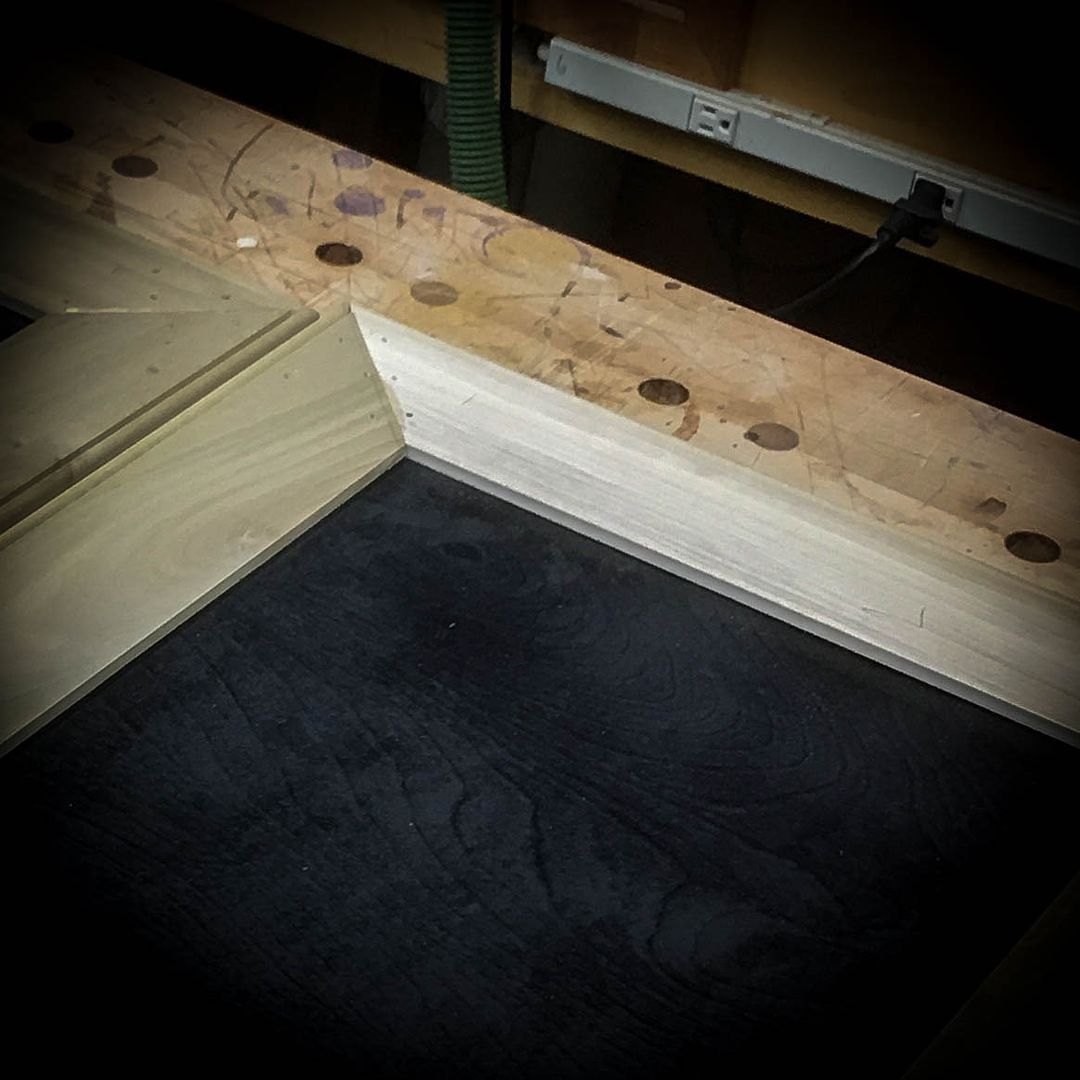

...and the drawer box parts are milled for traditional wood slides. One thing this project is providing is plenty of opportunities for fixing mistakes; things like a router bit coming loose while milling slots, causing too deep of a cut and some other little things. Rather than recreating components completely from scratch and wasting material (such as the cherry being used for the drawer boxes), I chose to fill the boo-boos with wood and move on since these things are not really visible under normal circumstances.

...and the drawer box parts are milled for traditional wood slides. One thing this project is providing is plenty of opportunities for fixing mistakes; things like a router bit coming loose while milling slots, causing too deep of a cut and some other little things. Rather than recreating components completely from scratch and wasting material (such as the cherry being used for the drawer boxes), I chose to fill the boo-boos with wood and move on since these things are not really visible under normal circumstances.