So I wish I would have left two more placeholder posts to cover today's activities, but alas, I did not.So I'll just start from here and remove the one remaining placeholder above. (that you'll not be able to see now 'cause it's gone. LOL)

Today's work focused on two things: 1) sizing and sanding the cherry buffet top and 2) creating the mechanisms for fastening the soon to be built upper hutch portion so that it would be absolutely secure and "one with the buffet" once installed in the house. While this isn't a terribly wide piece, it's going to be quite tall. (and yes, it will need to be fastened to the wall for safety once positioned so it cannot tip)

We begin by crosscutting the cherry panel to length. It's already been sanded smooth on top and one end trimmed relative to the front face. After measuring for length (52" in this case) the other end is crosscut indexing on the same face. That required flipping the panel over.

Similarly, the panel needs to be ripped to width (26" in this case) to get to final dimension

While the cuts are clean, it's a good practice to work the end-grain edge a little with a sharp block plane so that subsequent sanding is easier and the end result is close to "burnished"

And we pause to admire things as they stand in the moment...

In addition to what I'm going to be showing you soon, I chose to equip this piece with some strong angle supports at the back. Perhaps it's overkill, but I'd rather have that than the alternative. Using a router, I countersunk a slot so that the brackets were flush with the carcass surface.

A board temporarily clamped on helped to line up the brackets so that they would be flush with the back of the case. I drilled for and installed one screw in each to hold that position at this point.

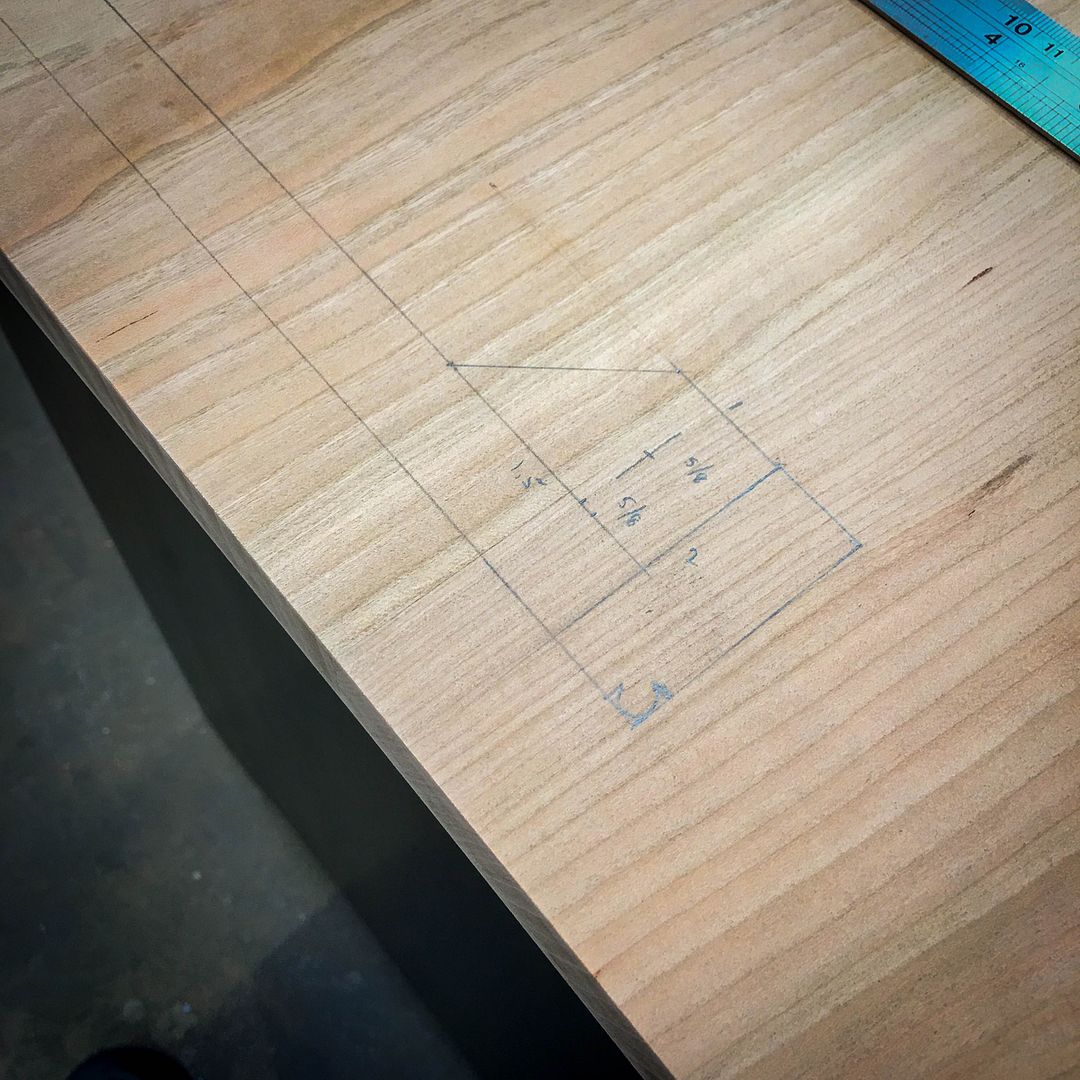

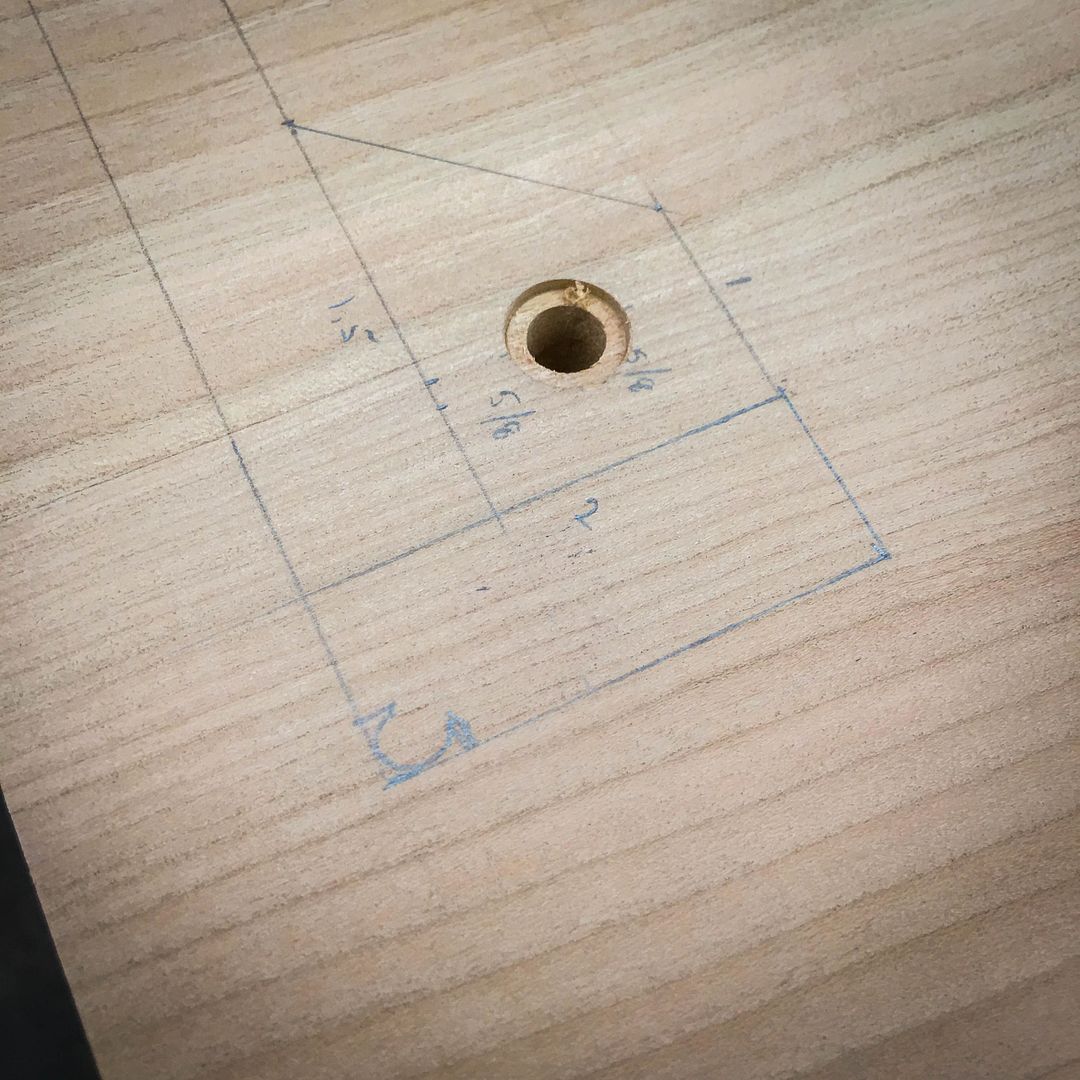

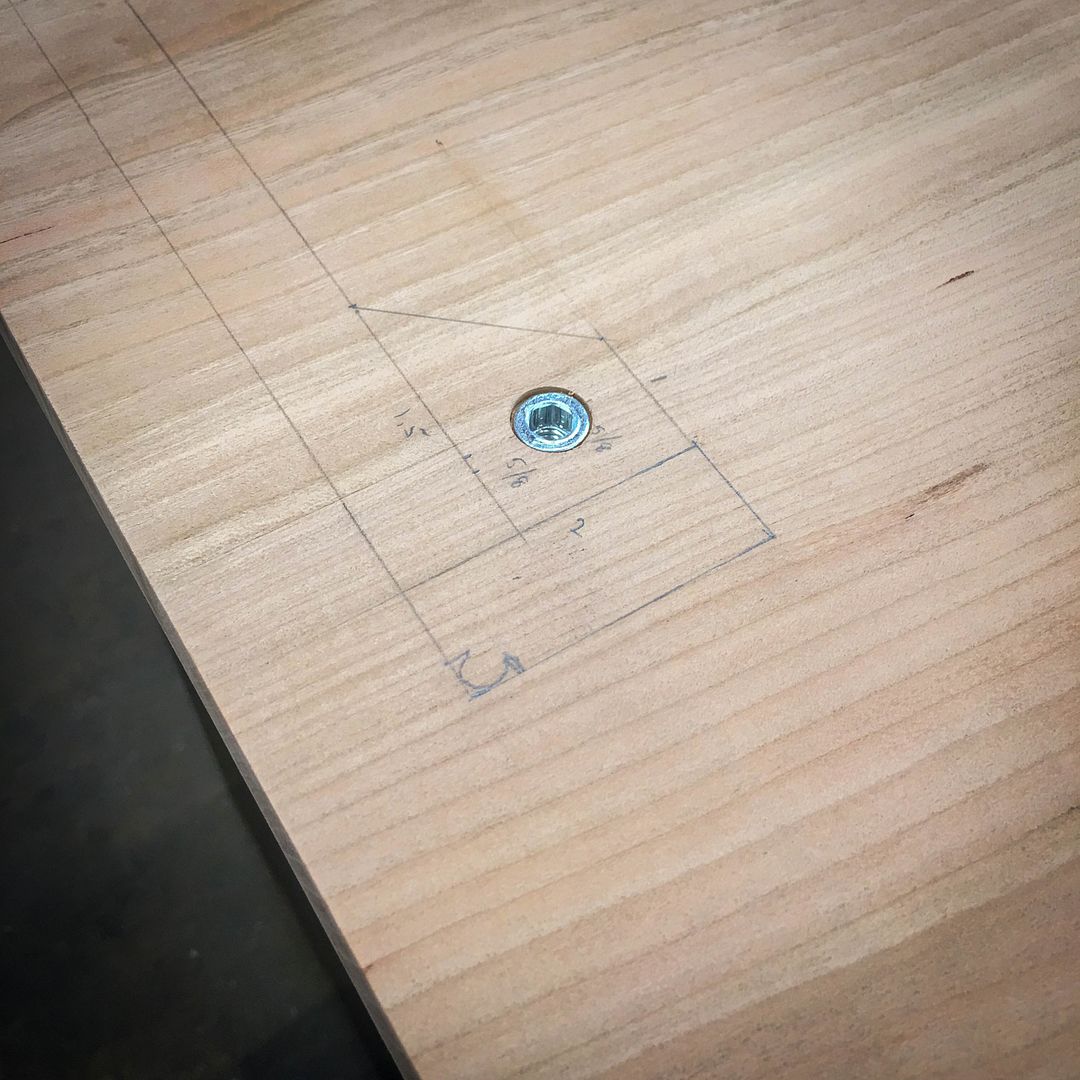

The slight curve in the bracket requires relieving the bottom of the cherry top to insure the top will go back flush. Here, the position is marked...

...and the deed is done...

At this point, I fully installed the cherry panel and fastened it down for the next interesting exercise.

Reply With Quote

Reply With Quote