I hooked up my air compressor with a 120V contactor (the contactor controls the 240V circuit, but the control part - the coil - is 120V), and then I control the contactor with a sensor that detects when I'm in the shop. The sensor is one of those ones you can buy to turn your lights on when you enter a room. I have a switch that allows me to turn power off to the sensor (which shuts off the contactor and thus the air compressor), and another switch that bypasses the sensor so the air compressor is always powered (the contactor is always powered so the air compressor is always powered).

I can have the air compressor on the sensor, turned off, or always powered.

I like it because I never have to worry about turning it on when I go into the shop, or turning it off when I leave. Often when I enter the shop, the air compressor will start running because it leaked a bit of air overnight.

You could do the same to provide power to your dust collector, and still control the dust collector with a remote control when this sensor is providing power to the DC. If you walked out and left the DC running, it would shut off when the sensor timed out.

Mike

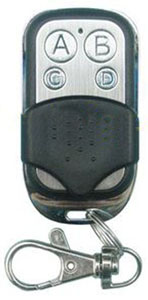

[Here's what it looks like from the sensor:]

Air-compressor-control.jpg

Last edited by Mike Henderson; 10-30-2016 at 5:40 PM.

Go into the world and do well. But more importantly, go into the world and do good.

Reply With Quote

Reply With Quote