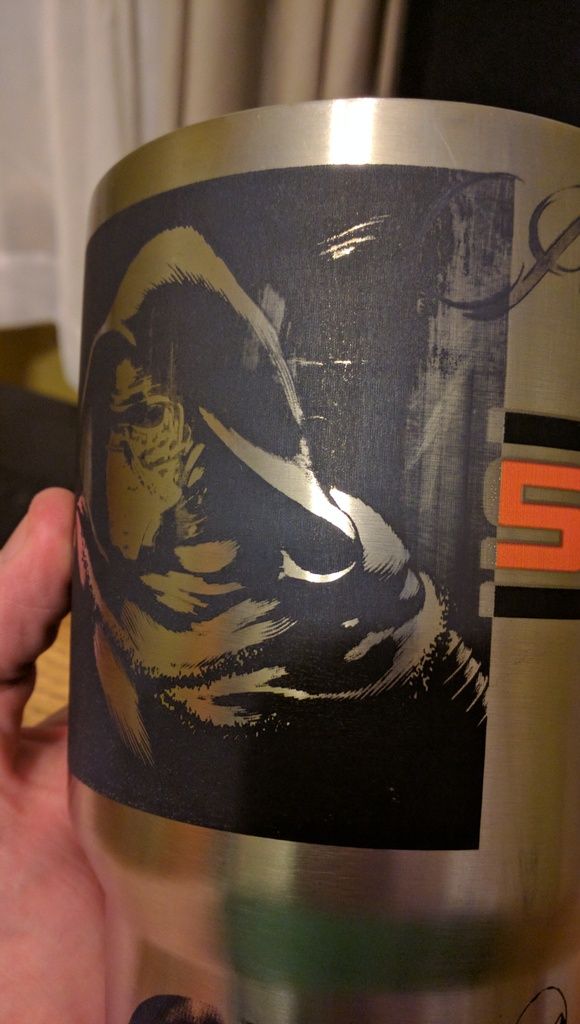

I've been experimenting with cermark on a yeti cup and I'm it's rubbing off. I'm using a 30watt VLS2.3 and before I sprayed on the cermark from the spray can I cleaned the surface with isopropyl alcohol.

First I followed I tried 100% power, 25 speed, 350 ppi. The images turned out well but when I rub on it, it begins to rub off

So I started to read through the forums and saw most people typically go slower then what I was using and use higher ppi.

This one is 100% power, 14 speed, 660ppi and I still get wipe off

Is this something that can happen if I'm applying to much cermark?

Reply With Quote

Reply With Quote

Make sure your PPI is at 1000. If you are at 30W, you probably do need to be between 10-20% on the speed. A 2% change in speed can make the difference in sticking or not sticking, so you have to dial it in very well. Start with 15%, 100% power, PPI 1000, Image Density of 5 and see how that works and go up or down by 2% on speed from there.

Make sure your PPI is at 1000. If you are at 30W, you probably do need to be between 10-20% on the speed. A 2% change in speed can make the difference in sticking or not sticking, so you have to dial it in very well. Start with 15%, 100% power, PPI 1000, Image Density of 5 and see how that works and go up or down by 2% on speed from there.

- fiber lasers

- fiber lasers