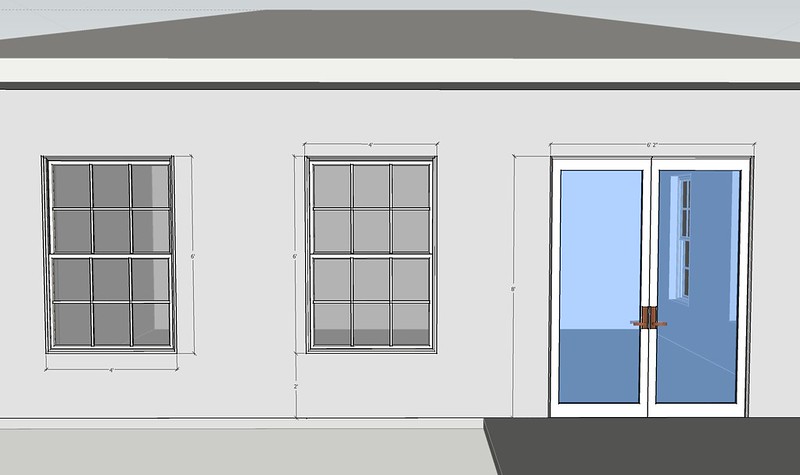

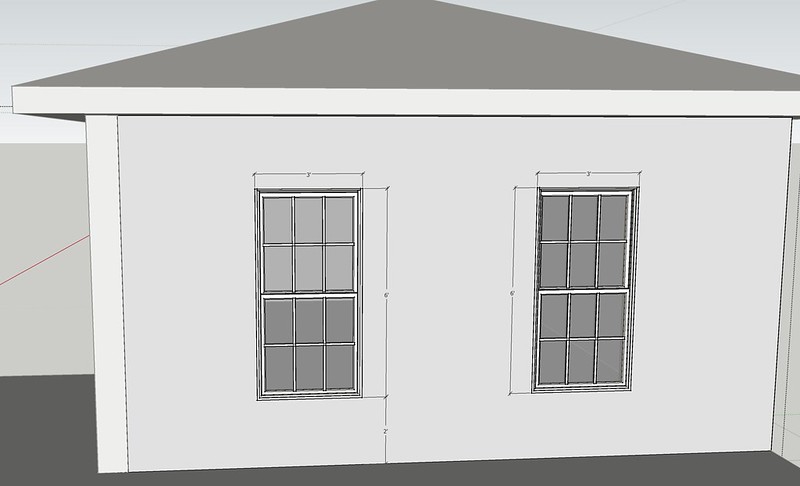

Could anyone recommend a resource for planning the fanout from my subpanel on a detached shop? I have a handle on the code portion, where to tack it down, drilling through studs, etc etc. What I'm looking for is 'best practices' in the context of a vaulted ceiling, where to locate the subpanel, tips to minimize cost, etc. It's a basic 20x28, hip roof, vaulted ceiling.

Thanks in advance. Will hopefully be starting a thread soon with my shop build.

Reply With Quote

Reply With Quote

) that has to be used which further reduces cost. However, that may or may not necessarily be optimal from a practical standpoint for a shop setup in some cases, such as with the vaulted ceiling you mention since you don't have as much choice for hidden and/or direct pathways to get to various places in the shop. The floor plan of your shop will play a role, too. If you're going to keep the majority of your machinery in one location and use other locations for less electrically intensive work, then having the panel closer to the machinery area means less wire to get the circuits placed to support those tools. Depending on the number of circuits, that could favor a longer feeder vs more distribution wiring. One other thing relative to machinery...if you are able to plan up-front where the tools that will be somewhere in the middle will be, you can then plan for the supporting circuits to travel in the floor. That might mean in conduit embedded in concrete or under the floor in the case of a crawlspace or basement. There are so many things that can affect how best to wire things up and your actual shop design is going to affect them.

) that has to be used which further reduces cost. However, that may or may not necessarily be optimal from a practical standpoint for a shop setup in some cases, such as with the vaulted ceiling you mention since you don't have as much choice for hidden and/or direct pathways to get to various places in the shop. The floor plan of your shop will play a role, too. If you're going to keep the majority of your machinery in one location and use other locations for less electrically intensive work, then having the panel closer to the machinery area means less wire to get the circuits placed to support those tools. Depending on the number of circuits, that could favor a longer feeder vs more distribution wiring. One other thing relative to machinery...if you are able to plan up-front where the tools that will be somewhere in the middle will be, you can then plan for the supporting circuits to travel in the floor. That might mean in conduit embedded in concrete or under the floor in the case of a crawlspace or basement. There are so many things that can affect how best to wire things up and your actual shop design is going to affect them.