This past weekend I cut up some really nice spalted pecan bowl blanks for my Adoptwood.com business. I decided to try one myself and make what would become the largest bowl I have made to date.

The wood cut great but was fairly soft in a few spots and tended to tear out on the endgrain pretty bad. I decided to try some stabilizing and it worked great. This is what I did:

I turned the bowl close to the final dimensions I wanted. I then mixed up some System Three epoxy and thinned it with alcohol until it was the consistency of real maple syrup. I took the bowl off the lathe and applie the epoxy to the bowl with a brush until it would not hold anymore. In a number of places it soaked all the way through the bowl even before I did the inside. I then let it cure overnight and mounted back on the lathe the following evening. Man it sure did turn nice! It turned like regular wood with really nice curly shavings.

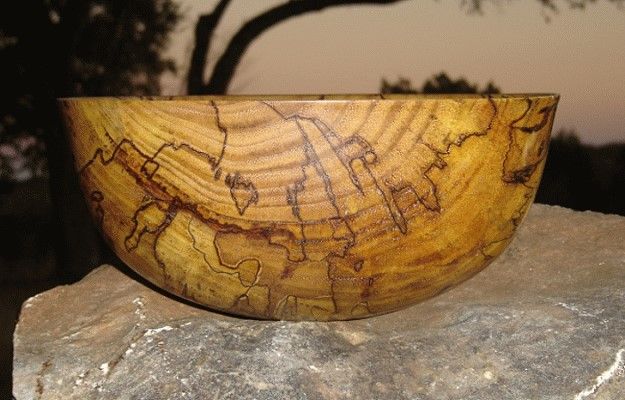

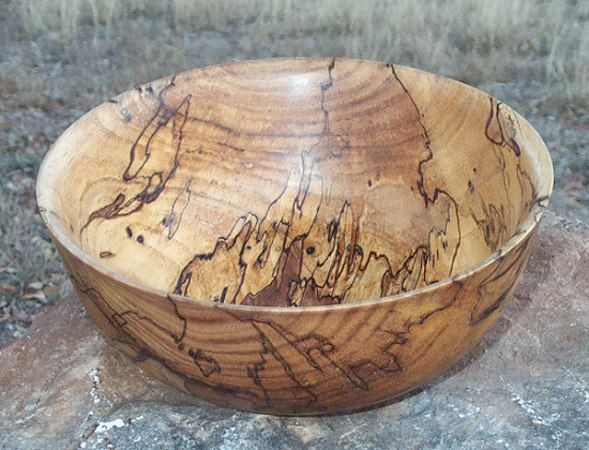

It also sanded very easily. I sanded to 12,000 mm and then applie BLO to bring out the color better. After that, it was a couple of coats of Watco gloss brushing lacquer applied as a friction finish with a rag. A final buff with a chamois and this is what I ended up with:

The bowl is 7 3/4" wide by 3 1/4" tall with wall thickness of just a hair under 1/4". It is my best work so far.

Please give me some HONEST feedback about the bowl and it's form. I am also looking for comments on my photo setting. It was done outside on a rock pile towards the end of the day with lite flash. Just a plain old 4.1 mp Sony camera on automatic settings.

Reply With Quote

Reply With Quote

. I'll have to try your method of stabilizing.

. I'll have to try your method of stabilizing.