From square to tapers to round tapers. This is the progression.

The easiest way I know to accurately turn tapers on legs is to shape the taper first. This is done on a parallel guide on my slider (just another taper jig) ...

Now it is much easier to turn to round and have consistent dimensions - 40mm diameter at the top and 25mm at the bottom ...

Note that the mortice is left open - some like to fill it for fear of spelching. I have not experienced this ... keeping the speed up helps.

With the first four legs completed, a preview of the the lines and offset angle of 3 degrees ...

In addition to the legs, the aprons were laid up and planed to width. The length is soon to be finalised. There are two sets of front-and-rear aprons, and two sets of side aprons. The fronts are thicker as these will received a bow to match the curve of the case ...

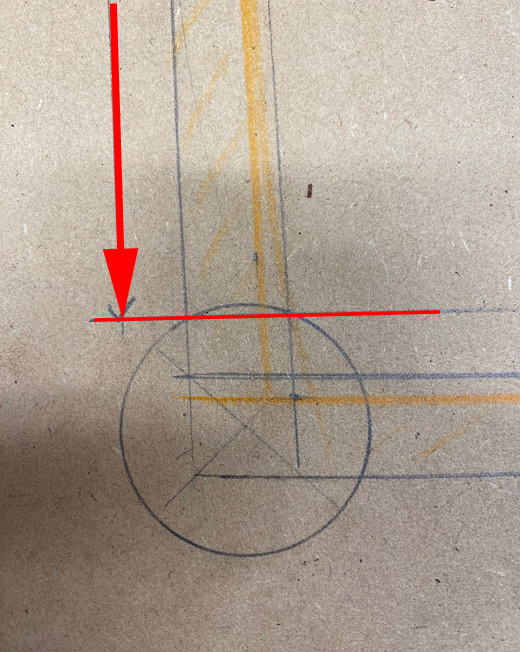

The plan is used to determine the length of the aprons. What is measured is the length of the top of each rail ...

To fit the flat end of each rail with the round of each leg, the legs will be recessed. Consequently, the measurement includes the recess ...

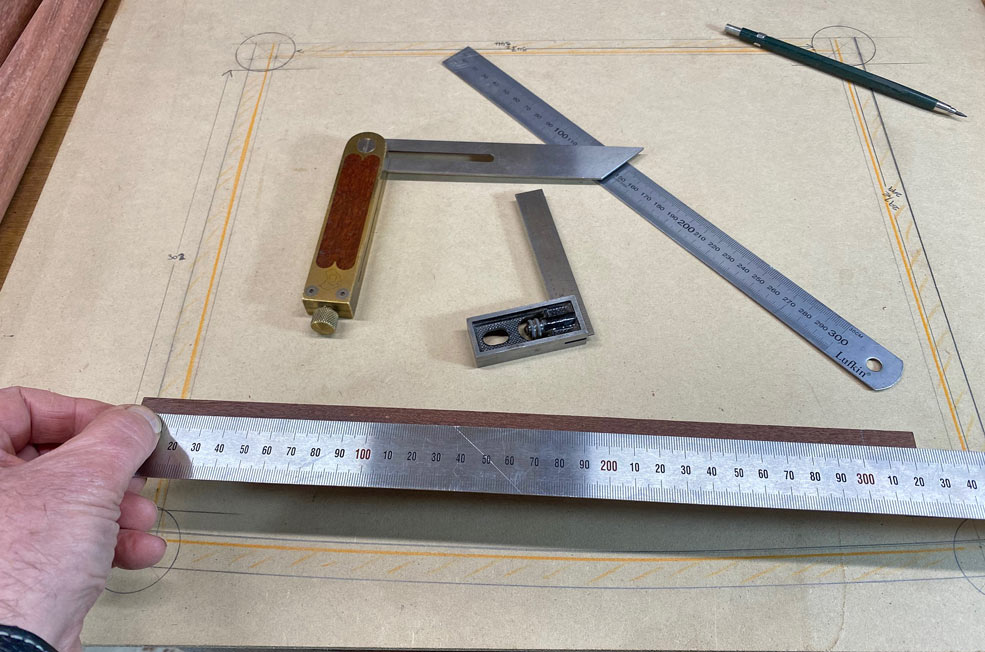

A zero clearance sub-fence from scrap is added to the crosscut fence on the slider. The saw blade is angled at 3 degrees.

One side is cut, and then the length is measured ...

... and then the other side is cut ...

Another mock up ...

Everyone is now cut to length, and mortices added ...

That's it for the weekend. More later.

Regards from Perth

Derek

Reply With Quote

Reply With Quote