I am fighting the start button on my Felder K700 slider. It is almost impossible to reach with any panel on the saw. Actually the last time I cut one, I had my almost 5 year old GG son crawl under and push the button. I usually push it with a stick. Pretty Mickey Mouse, I know.

It is a 2014 model, and I know they offered a remote button, but mine does not have it. I cannot find it on the Felder site, and probably couldn't afford it anyway.

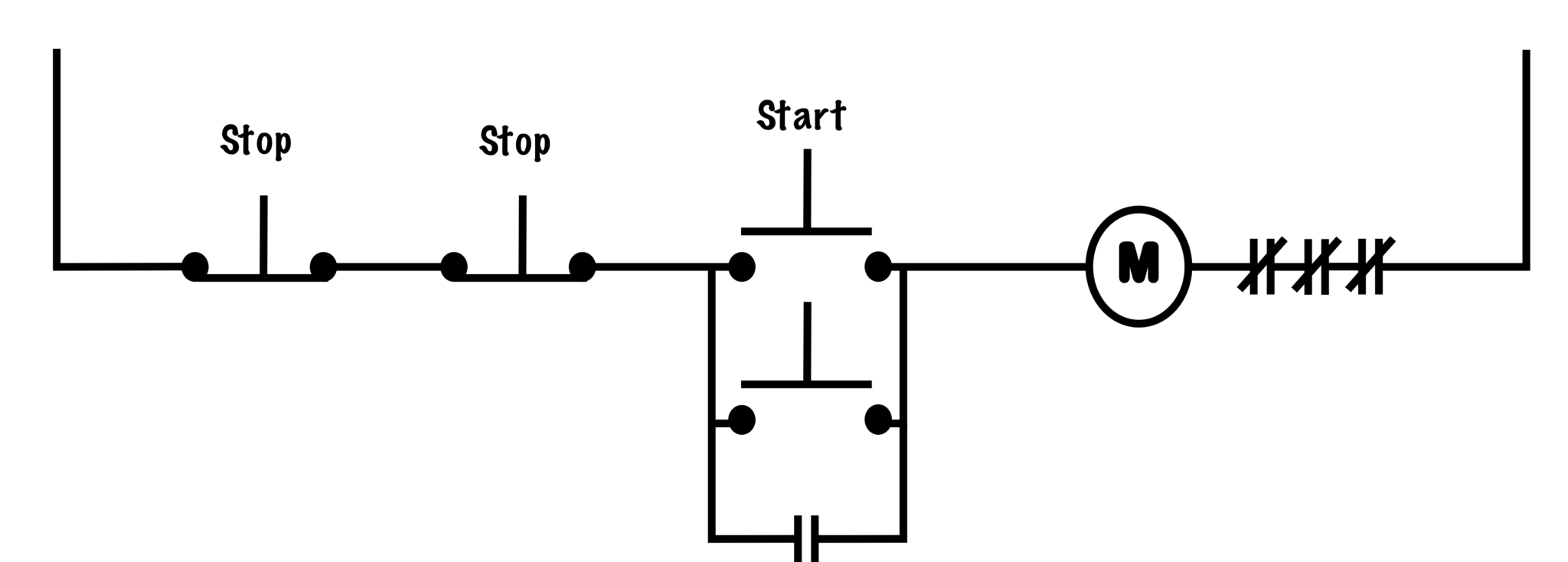

Anyone know what I need to install a remote start button. Stop button is no problem when cut is finished.

Thanks

Reply With Quote

Reply With Quote