Hello... lots and lots of raving and pictures. So, please be warned.

I've got bit of a fascination for cutting profiles cleanly across grain with hand planes. Spend all day thinking about this sort of stuff. Can't help myself I'm affraid. Thought I'd write it down before somebody pinches my idea...maybe give someone a few ideas.

This threads just a continuation, I suppose of these ones.

http://www.woodworkforums.ubeaut.com...ad.php?t=33429

http://www.woodworkforums.ubeaut.com...464#post326464

http://www.woodworkforums.ubeaut.com...ad.php?t=34409

This ones about raising panels. And as you know, that involves cross grain cuts. Here's what I did today using my stanley 55. Just a basic profile.

Notice how clean the cross grain cut is in that last picture. Now compare it to this sample, which was cut with a regular blade in my stanley 55 some time ago. Tear everywhere, caused by the blade presenting itself against the grain. Same old problem as described in those links above.

The solution again is to skew the blade like in those other threads. Unlike the other planes, with their smaller cuts, the blade for panel raising is a lot wider. The only way I could see to skew the blade enough to benifit the cut was by tilting the plane over.....show you what I mean.

The more you tilt the plane over, off vertical like this

the more the blade skews off square just how I want it...

Found it a bit tricky to visualise myself. But a skewed blade is just what you want for going cross grain. Bedding of planes like the stanley 46 and 39 are similar looking. The beauty of it also is that they cut nicely with the grain as well, so you can use the same plane setting to do all 4 sides of your panel, or whatever you have in mind.

So in use the plane is pushed with it tilted over...surprisingly comfortable too. Feels similar to using a sprung woodie.

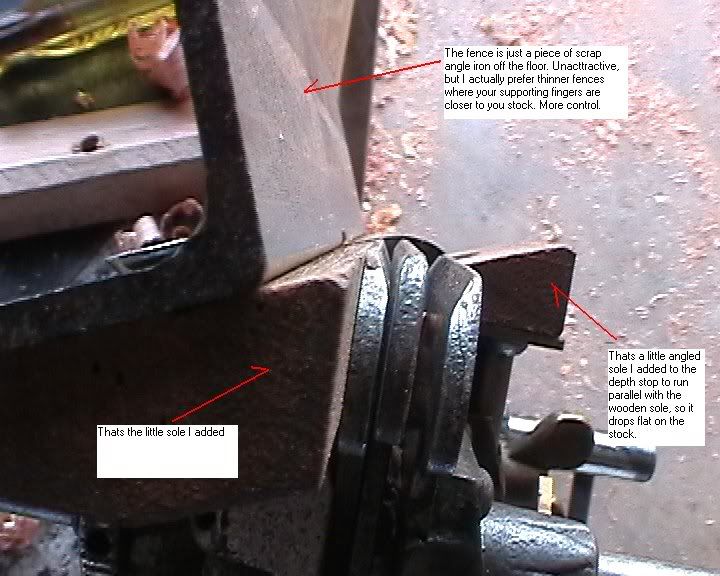

Another problem to deal with, was the instability problems of the stanley 55. There not really built to support wide cuts like panel raising. IMO, they seem ok if both skates support the work from the very beginning, else often, at least I find, the planes just too difficult to keep stable.

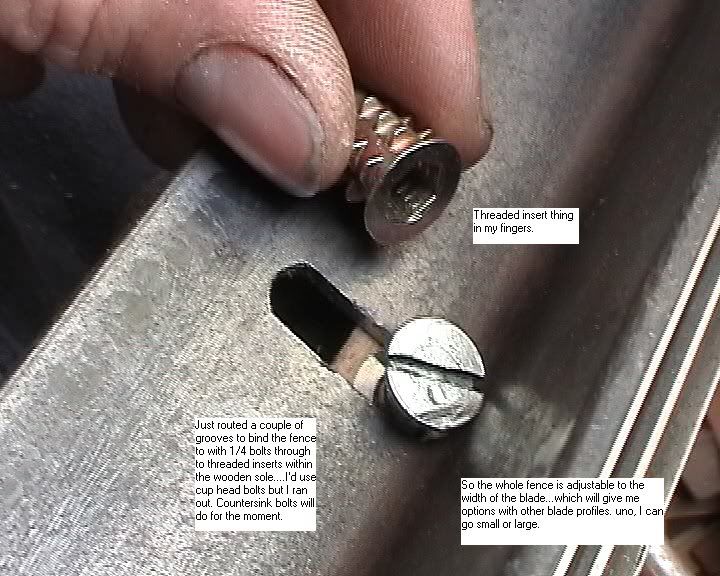

To solve that I decided to add a wooden sole to the adjustable skate.... just a flat sole, that cuts around the tongue common to most profiles. ie. figured I still be able to use varing profiles, whilst generally improving the 55's stability for wide cuts.

More next post.....

Reply With Quote

Reply With Quote

yes...and I reakon some would say they don't even make a good anchor too....actually probably many would say that.

yes...and I reakon some would say they don't even make a good anchor too....actually probably many would say that.

Makes me appreciate my other combis even more, I can tell you. Never trust a plane that's in immaculate condition...

Makes me appreciate my other combis even more, I can tell you. Never trust a plane that's in immaculate condition...

Jr.

Jr.