Probably like many of you, my workshop is too small for the number of tools I have in it. I'm continually having to move machines around so I can get enough in/out feed clearance for the work. Also, my mortising machine and sliding combination miter saw have no real home - they get moved all over and get in the way. There is hardly enough space to walk between my machines/piles of wood/storage containers etc. and I'm always scraping my legs while moving around the workshop.

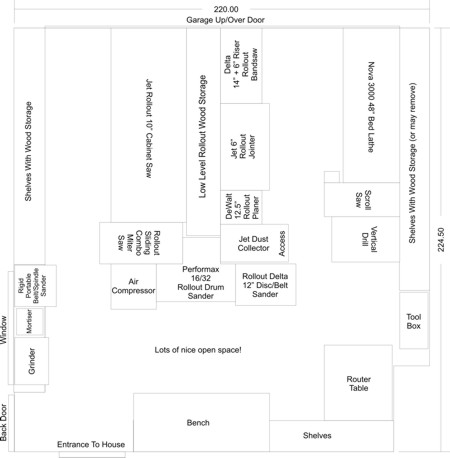

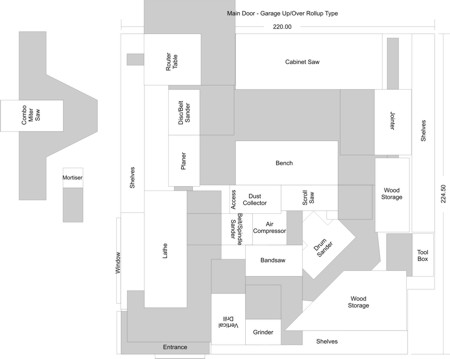

Recently I decided I'd had enough! There has to be a better way to layout my 'shop. So, I measured everything carefully and entered it all into a Corel Draw (X3) drawing, using 1mm = 1" scale. For your amusement, here's a picture (click on it to see it bigger) of my current workshop layout and the Corel Draw X3 file.

http://www.daveswoodenwonders.com/Layout_101506.cdr

As you can see, the miter saw and mortiser don't have anywhere to go and there's no space for in/out feeds from many of my machines (e.g. jointer, planer, bandsaw). If I want to use my router table, or cut anything over about a foot long on my cabinet saw, I have to raise the front garage door (which then blocks the lights in the ceiling).

I have a few ideas about how to juggle everything around and make it fit better, but I thought I'd poll the experts (that's YOU!) to see what changes you'd make. Feel free to play "jigsaw puzzle" with the Corel file and post your improved layout ideas (if you have Corel Draw that is). I can post a version 11 or earlier file if anyone wants one to play with.

The shelves that go all the way round the garage are floor to ceiling except under the window by the back/kitchen doors. I am not averse to removing any or part of them. For instance, I may remove the bottom part and just leave a high shelf with machines under some of them and I may turn the shelf unit behind the lathe into a plywood sheet storage unit. Right now, I can't really get to many of the items on the shelves anyway....

I'm looking forward to seeing what you come up with.

Thanks for your help,

ave F.

Reply With Quote

Reply With Quote