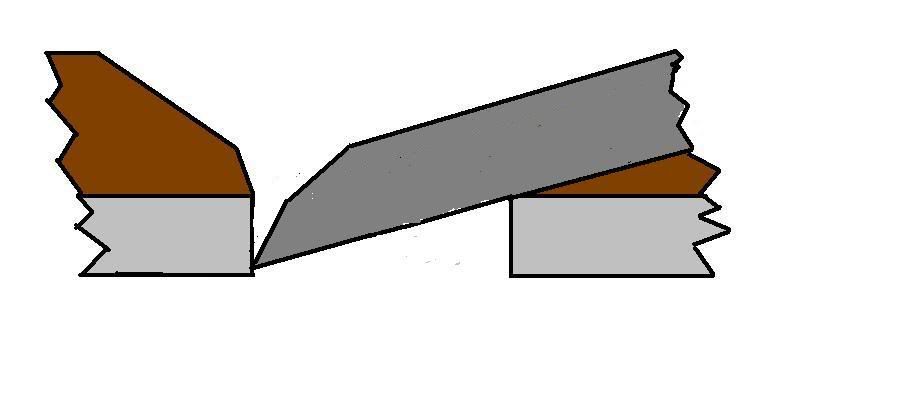

OK, I'm thinking real hard and umm... taking time from my schoolwork() to sketch ideas for an infill. I've got the bed from a Sargent made Craftsman thats going to be perfect for it. I just have a few questions. How do I mill out the insides of the bed?-and-What do you think about this initial rough sketch? This plan is going to have Bailey adjustments in a east Indian rosewood frog/handle, yup I'm shooting for the sky. Thanks in advance. Maybe I will be able to get the picture to attach.

-Ryan C.

PS- Please forgive the sloppiness of the attachment.

EDIT: Forgot to say that this will most likely not be used for anything except conversation due to the inherent fragility of the wood and the pressure of the adjustments.

Reply With Quote

Reply With Quote

55 degree bed, LN blade, Mathieson cap iron

55 degree bed, LN blade, Mathieson cap iron

.

.

to get the results needed.

to get the results needed.