Hello--

was gressing up a slim little piece of oak to make a picture frame with--about 2x 1/2 times several feel long. this was an excuse to use some of my tools I have been obtaining but still am just learning to use...

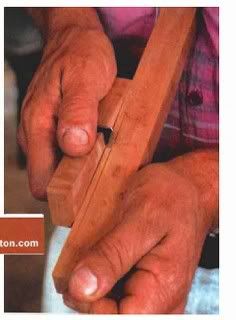

I cut a rabbit with a stanley 78 and cleaned it up with my new to me sw marked 79. Was pleased with the result--will work well on the back of the frame.

For the decorative part, I used my stanley 45 ( have never used it before on any real "project...") to make 3 bead. I set it as low as possible and ultimately came out with 3 nice beads running the length of the 3 foot board. Nice, but the 45 did a lot of getting hung up and it certainly wasn't the nice smooth cut for the beeds I had hoped for. Philosophy on the 45? It seems to have potential, but also, I have read about a lot of people who don't like it and suggest having a collection of other tools and planes instead.... how about the 45 for dados and rabbits?

Another option I have considered is obtaining a 66 or moulding plane for such tasks... Thoughts?

One of my basic recurrent questions has to do with the combination planes; Are there folks out there who use the 45 and or 55 as a mainstay for beeding, moulding, etc; otherwise stated, are these tools interesting odities or can they be made workhorses in the amature woodworkers shop?

Broad questions of function and philosophy, but will be very interested in hearing what everyone thinks about this stuff!

Thanks, Jeff

Reply With Quote

Reply With Quote