I’ve had a Festool MFT 800 table and the TS 55 EQ saw for almost two years now. I love the saw and table combo, love their other tools, the table setup has many uses, saw is extremely versatile...

My only problem with the table is that no matter how hard I try, I can’t seem to get perfectly square AND repeatable cuts on plywood panels – 23 x 32 inch in that size range. I think I was able to do it a few times with an extreme amount of fiddling with a precision triangle, lining up the guide rail perpendicular to the fence, but it takes a lot of time and it seems after a while, it goes out of alignment, and then I have to spend a lot of time again getting the rail aligned perfectly. Most of the time I can get the corners pretty darn close to square, just not as square as I think I could with a good cabinet saw. Making accurate and repeatable angle cuts in large panels is also a problem. I’ve never owned a table saw so I have not been “tainted” yet about not being able to utilize the festool.

Anyway, I gave up on attaching the guide rail to the table and I went out and purchased a Pinnacle cabinet makers square, now I just cut a straight edge using the guide rail un attached to the table - laying it down on plywood, first I scribe a perpendicular line in plywood using the Pinnacle, lay the guide rail over the scribed line, and if I really take my time, I can get a perfectly square corner, but sometimes even that is not repeatable, it is more repeatable than were I to use the guide rail attached to the MFT and use the fence though. Either method takes a lot of time to get perfect.

I looked at the new MFT table which came out earlier this year at my local dealer, it looks beefed up a bit - a bit more stable, but I still don’t see how it can solve the repeatability problem. I keep thinking that extruded aluminum and MDF is no match for a cast iron table top and precision t-saw fence.

So It’s gotten to the point that I’m considering dropping another grand and purchasing a Grizzly G1023SL table saw, and then just use the Festool as a panel saw and build table, sanding table, etc. But I want to exhaust all possibilities first with the MFT to see if I can get repeatable square cuts somehow, either by using a different technique, maybe retrofitting the table somehow, maybe I’m doing something wrong, before I drop another grand.

Has anyone actually been able to get perfectly square AND repeatable square cuts on plywood cabinet panels with the MFT 800? Either with the standard Festool accessories, or retro fitting the table somehow?

If so, howdja do it?

Reply With Quote

Reply With Quote

There is another popular brand of saw guide that some people are adapting to their festool stuff in order to get really good results with little effort. If you can't make what you have work you might want to look in that direction...Isn't making square cuts sort of a requirement and a very basic task? Good luck and I hope you get it figured out.

There is another popular brand of saw guide that some people are adapting to their festool stuff in order to get really good results with little effort. If you can't make what you have work you might want to look in that direction...Isn't making square cuts sort of a requirement and a very basic task? Good luck and I hope you get it figured out.

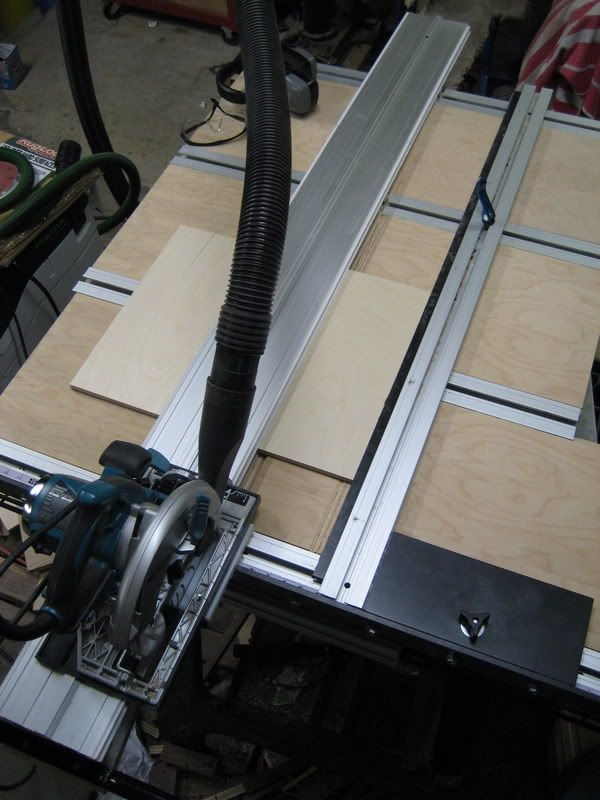

Many are starting to combine the festool stuff they have with some EZ stuff to make it work better. Some are then selling off some of the festool stuff and buy the EZ tools. Some are keeping what they got and just combining the two. Either way, you're welcome to the forum, even if you never buy any EZ tools at all.

Many are starting to combine the festool stuff they have with some EZ stuff to make it work better. Some are then selling off some of the festool stuff and buy the EZ tools. Some are keeping what they got and just combining the two. Either way, you're welcome to the forum, even if you never buy any EZ tools at all.