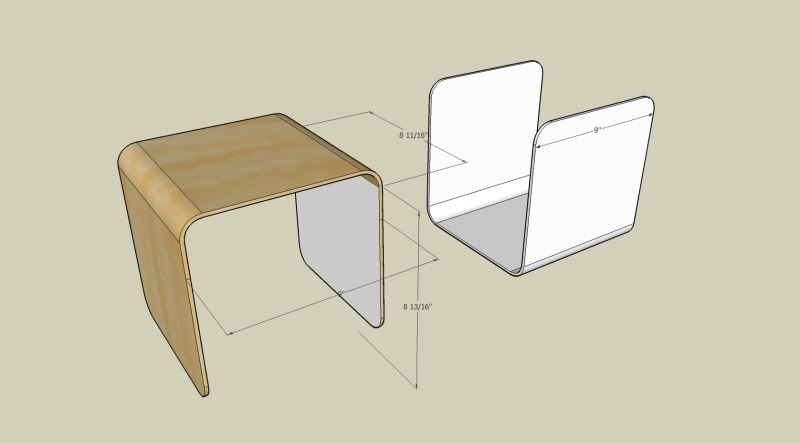

I'm going to attempt this bent ply shape as an experiment/learning experience. Can anyone give me some tips?

I was planning on using very thin sheets of veneer glued together, to build up the form one sheet at a time. Will it be able to hold this shape without any interior support?

I'm planning on mating this bent ply form with a similar aluminum form, to create a simple box.

Reply With Quote

Reply With Quote