Machine cut or hand cut - that's the question. My feeling theses days is that if you are hanging a drawer box on souped up ball bearing side mount slides or the Blum Tandem types, dovetails are an affectation - practically any kind of connecting the parts will do. There I said it

.

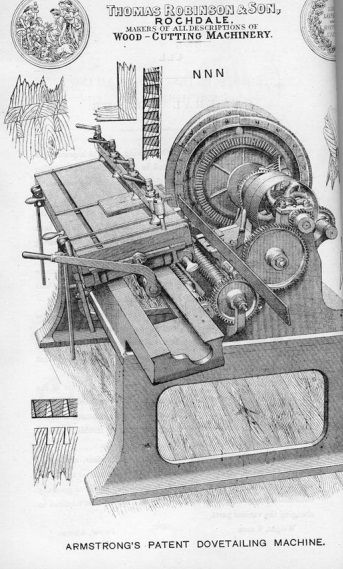

Otherwise - I like the look and the process of handcut but I envy those guys who have the tools to mass produce - often would come in handy.

jack forsberg is my hero in this thread.

Reply With Quote

Reply With Quote