-

To conclude this thread...

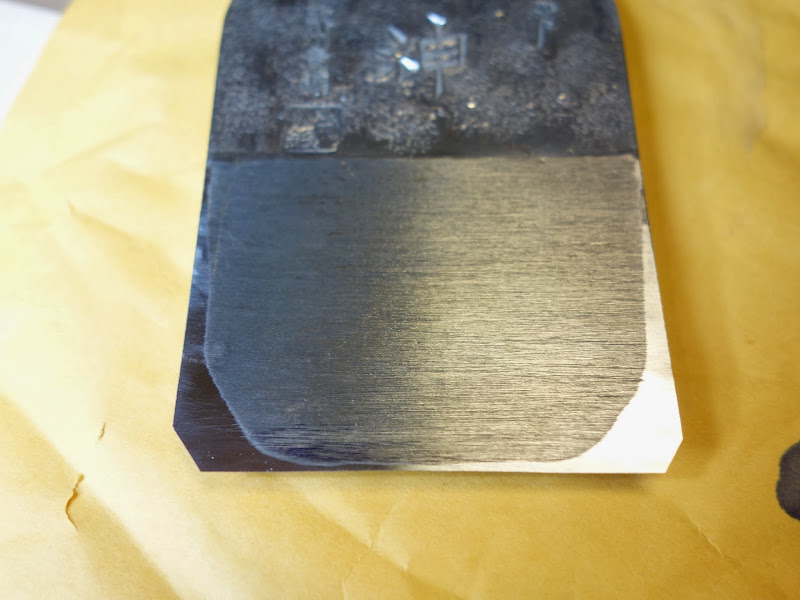

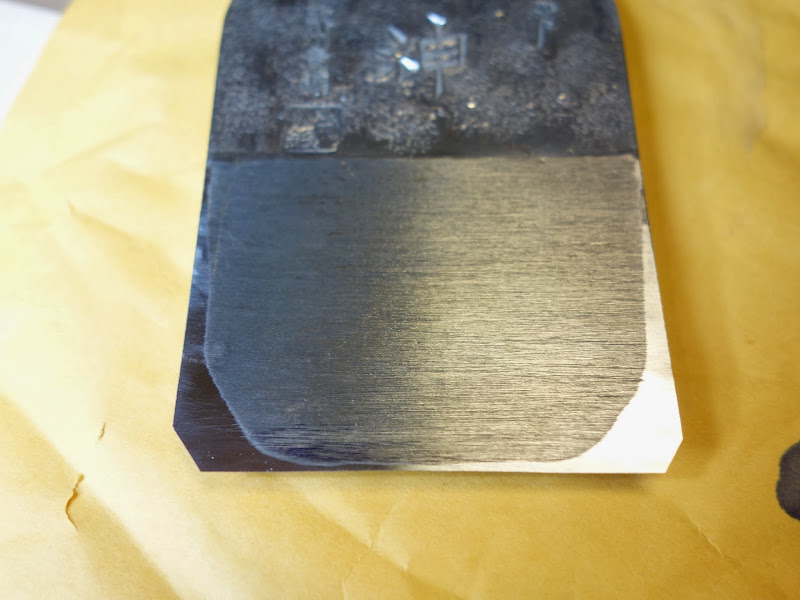

While grinding the plane blade down, I uncovered a defect (or two) in the blade. As I ground the blade down near my scribe line, I noticed a black smudge on the ground part of the blade. I assumed it was just metal filings and water, as I just quenched the blade. I made another pass and found the black spots still there. On closer inspection, they are voids in the hard layer of steel. I am making the assumption that these voids right at the base of the crack line, caused the fracture.

I was able to recover the blade and tap out the ura. This blade was very difficult to tap, and I had to hammer dangerously low on the soft layer of the bevel to eek out barely 1mm of flat. I somewhat forced the process by excessive flattening of the back, so the ura is not very attractive. In future, I will switch to a more pointed hammer, as Wilbur suggested.

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

Reply With Quote

Reply With Quote