I'm not sure which forum this should go in, but this seems to make sense.

I have another thread going (re: waterlox) that shows some progress of a kitchen island project I have going on. That is still under way. The wood finishing is done, but it hasn't been put together just yet. And we've yet to remove the wall that'll have to come out to make room for the island!

Anyway, I'm working with 3-inch slabs of sapele for the island, and had a really nice piece of "scrap" from cutting the slabs to size. Clearly, it's not scrap--it's really beautiful wood! I considered making this a shelf in the middle of the island, but it's a little too big, and it's just too nice to use like that. It deserves to be seen.

So I've done several pieces working with black iron pipe and flanges for legs/uprights, and considered going that route for this piece as well. I decided it would make a nice large side table (it's 32" X 42"). But then I figured that maybe I could find someone to weld me some cool legs out of steel.

And THEN..I thought, maybe I can design my own legs! A buddy does some basic welding, and taught me how to do it (stick welding, a 50-year-old machine but it worked fine). So I drew up some kinda funky, cool leg concepts, and went with one that I thought would look cool. I wanted an off-kilter look, but I wanted it sturdy (this is a large, heavy piece of wood). This design delivered both!

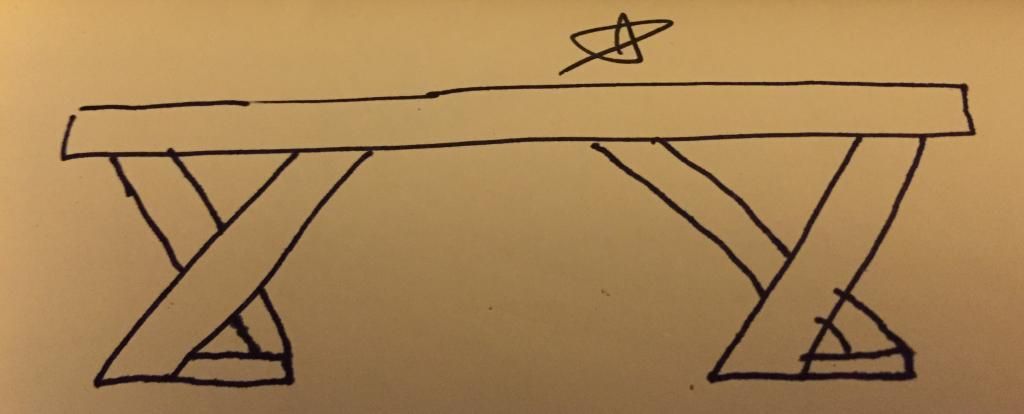

So here is the leg design in a sketch:

Uprights in the front are parallel but angled to the side, with the uprights in the back oriented opposite. Connected at the top and bottom. I used 1X3 rectangle box steel, 11 gauge I think (fairly thick).

Here's the steel after I completed the welding.

As you can see, as you change angles looking at the legs, they really change thier look. I've never seen legs done quite like this (though I gotta think someone has done this). But they're sturdy as they can be, and really sturdy as a pair. The table is rock solid!

Here's the finished table (wood is Sapele finished in Waterlox OSF, legs are steel and will be heated and waxed with bowling alley wax to prevent oxidation):

And a quick video walkaround:

So for me personally, this project had a number of firsts:

1st time working with Sapele

1st time working with Waterlox OSF

1st time working with a slab like this (or like the giant ones on the kitchen island)

1st time designing my own table legs

1st time doing any metalworking of any sort

1st time welding

And for all those 1st times.....I'm incredibly pleased with how this came out. I'm not the experienced craftsman that many of you are, I'm just a hobbyist that does some basic stuff with basic woods usually.

Whaddayathink?

Reply With Quote

Reply With Quote