Well here we go. This will out line some differences in the two saws for everyone. I borrowed a buddies TS55 and we compared them head to head.

Physically they are very close in size and weight. The Dewalt is slightly taller and wider by about one inch. The Festool Systainer is much nicer than the Dewalt box but both are adequate to hold the saws and the clamps. The Dewalt power cord is about 12' long and the Festool power cord is about 10' long. The Festool has a removable plug like all their tools and the Dewalt's cord is attached. The Dewalt guard allows the saw's blade to run parallel to the floor. This is not as possible with the Festool saw. There is the same amount of metal and plastic on each saw. Fit and finish I will give to the Festool but the Dewalt looks more rugged.

The Dewalt saw can use the Festool track with no problem. Festool saw cannot use the Dewalt track. Has to due with the guide tracks - three on the Dewalt and one on the Festool. the Dewalt saw can also use both sides of its track and only one side can be used on the Festool.

The Dewalt clamps fit the Festool track and the Festool clamps fit the Dewalt track. The Dewalt clamps are an optional accessory.

Both saw blades use a 20mm arbor. Blade changing is just barely faster on the Festool and the controls to do it are simpler on the Festool but to get to the arbor screw both saw had tooless motions. The Festool button motion locks the blade and the Dewalt requires holding in a spring loaded lock while loosening or tightening the bolt. Both saws took about the same amount of time to change a blade and both use a keyed arbor washer and Hex Head bolt to attach the blade. Both saws have hex key storage in the handles.

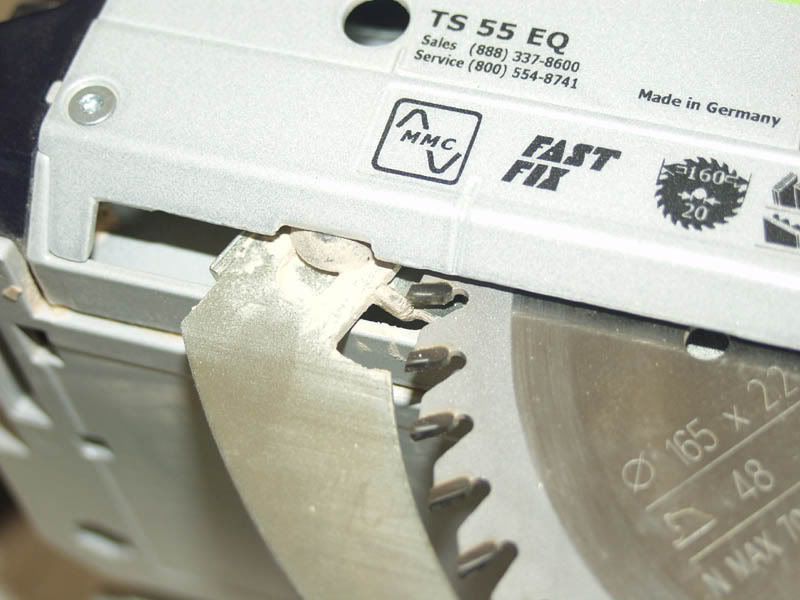

The Dewalt blade is just a few fractions/mm larger diameter wise than the Festool Blade. These fractions on the Dewalt blade conflicts with the mechanism of the riving knife on the Festool TS55 saw. So out of the box, with no saw mods, the Dewalt blades are NOT compatible with the Festool Saw.

We found that with a very small grind (with a Dremel or whatever) the problem could be alleviated with the TS55. My buddy said if the price of the Dewalt blades is significantly lower that he would consider grinding the post - but otherwise he will stick with Festool blades.

The Festool blade mounted just fine on the Dewalt saw.

The Dewalt saw guided smoother on its track with all of the play removed than my buddies saw Festool saw guided on his track with all the play removed. In fact I believe my friend has been using it with some play. I think my friend just needs time to adjust his saw perfectly. The Festool saw however is easier to adjust for play and on the Dewalt that option requires a hex key wrench.

Also the Festool saw does not have an anti reverse option. On the Dewalt saw, when anti reverse is turned on, the saw will not slide backwards on the track.

Both saws use a 1 3/8" internal diameter dust collection port. The Fein adapters on my Porter Cable hose worked (hooked to shopvac) on both saws and the collection hose of my friends CT22 Festool vac worked on both saws.

Startup sounds the same on both saws and you instantly realize the soft start on both models. Both saw running are about the same loudness. The lock you press to engage the plunge was smoother on the Festool. It is more of a positive click lock on the Dewalt.

The plunge action of the Dewalt is more of a plunge action than the rocking motion of the Festool. There are two pivot points on the Dewalt saw vs. the one on the Festool. The motor assembly of the Dewalt moves more into the plunge action because of the dual pivot points than does the Festool. The Festool rocking action was smoother however than the plunge of the Dewalt. Both were easy to plunge and can be done with one hand although the manual recommends two. The Dewalt had no resistance during its plunge but resistance was felt by us both in the rocking action of the Festool and by the geometry of the round blade entering at an arc in the pivot of the Festool.

The Dewalt saw has LESS VIBRATION than the Festool. I was shocked at that one. It is close, but that was a plus to Dewalt. Both have variable speeds and both were at max. Now the Dewalt saw spins at 1750-4000 min and the Festool spins at 2000-5200 min. That may have been the vibration difference.

Also the cut was better with the Dewalt blade on the Dewalt Saw vs. the Festool without the splinter guard, the Dewalt does NOT have a waste side splinter guard. Now my buddies blade/guard was not new so that is a factor however the blade was clean (we cleaned the blade prior to the review). With the splinter guard on both saws cut perfect. Also note, when I say better it is only marginal - these saws both cut to a high level of quality. I can see why they say table saw cut quality.

Cutting was done with 1/2" birch plywood and all the cuts were great (as long as Festool had the splinter guard on). We did not use the clamps much but did place anti-slip mat under the work piece.

Another plus to the Dewalt was the setting of the blade depth. It takes into account the track. I tried to show this in the pictures below when both saws were set to zero. If you set the Dewalt to 5/8" it is 5/8" below the track on the Dewalt. That is not the case with the Festool as 20mm is 20mm thickness including the track. The Festool does have a nicer mechanism to set the depth (push in and move) vs. the screw down system on the Dewalt. Both have a nice positive lock when the plunge is returned to full upright position.

Summary:

Dewalt Pros

---------------

1. Longer Power cord

2. Guard can run against Floor for door trimming

3. Dewalt can use Festool track

4. Can use both sides of the Dewalt track (for out and back cuts or with zero clearance set for two different blades)

5. Dewalt can use Festool Blades

6. Dewalt can use Festool clamps

7. Has selectable anti-reverse option

8. Slightly slower speed setting range

9. Dual Pivot plunge action and plunge action had no resistance

10. Less vibration than Festool saw at max speed full power (Festool is faster though)

11. Better no splinter guard (no option for one is bad though) cut

12. Better blade depth measurement system that includes the track already in the measurement

Festool Pros

-----------------

Slightly smaller footprint

Nicer carrying case

Systainer

Nicer fit and finish (I like the Festool look though!)

Detachable cord

Faster Blade Change

Arbor lock built into blade change button system

Smoother plunge button and pivot was smooth

Higher max blade spin rate

Splinter Guard option

Nicer Depth stop mechanism

Pluses for both

-------------------

Clamps and I am assuming other track accessories will work on either brand of track

With a slight Festool mod both saws will use each others blades

I did not review company or customer service qualities - just the two tools in my shop. Also I still need to compare warranties of the two tools.

Hoped you like the write-up.

Mike Heidrick

BloomingtonMike

Reply With Quote

Reply With Quote