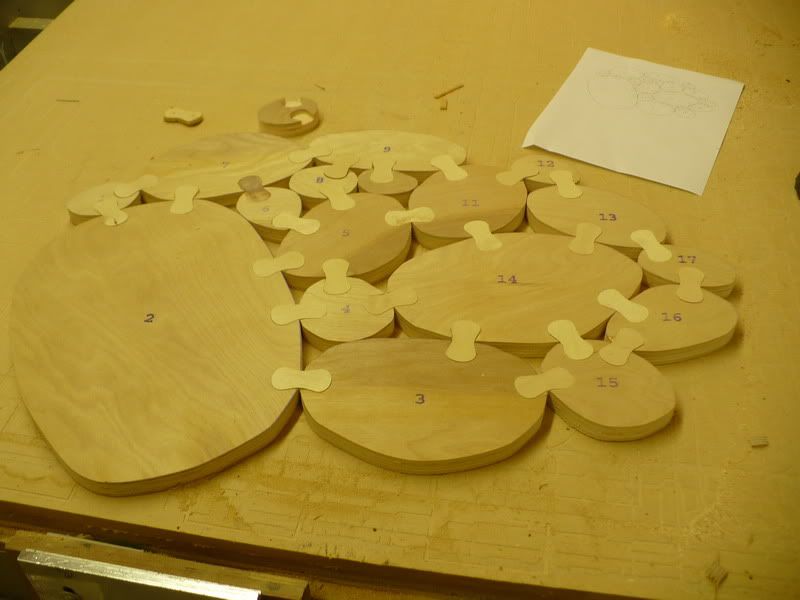

I had a customer wanting me to cut the pieces out for an unusual table he makes. a bunch of odd shaped circles joined at the edges. he has been using a domino for the job. but it took him a long time to cut them to sand them and join them. so he sent me a jpg file I imported it modified the butterfly/dogbone piece and off I went it worked the first time that surprised me a bit. I cut them on my cnc router out of 3/4" birch ply and some appleply for the dogbones. I think I will shorten the length in the middle of the dogbones by a tiny bit so they pull the pieces tight. I am debating on cutting them with a taper too as they can mash the edges if your not careful.

Reply With Quote

Reply With Quote