Hmmmmm, I don't see a jointer anywhere. I mean, I saw a picture of one sooooooomewhere in the begining of this thread, but I didn't see one delivered...

Hmmmmm, I don't see a jointer anywhere. I mean, I saw a picture of one sooooooomewhere in the begining of this thread, but I didn't see one delivered...

I drink, therefore I am.

JR,

I don't see why it would be a problem. I think I would start out with lacquer thinner and a tooth brush, and clean it good, followed with compressed air. Then I would use a light coat of a dry lubricant to keep it from rusting.

Sam

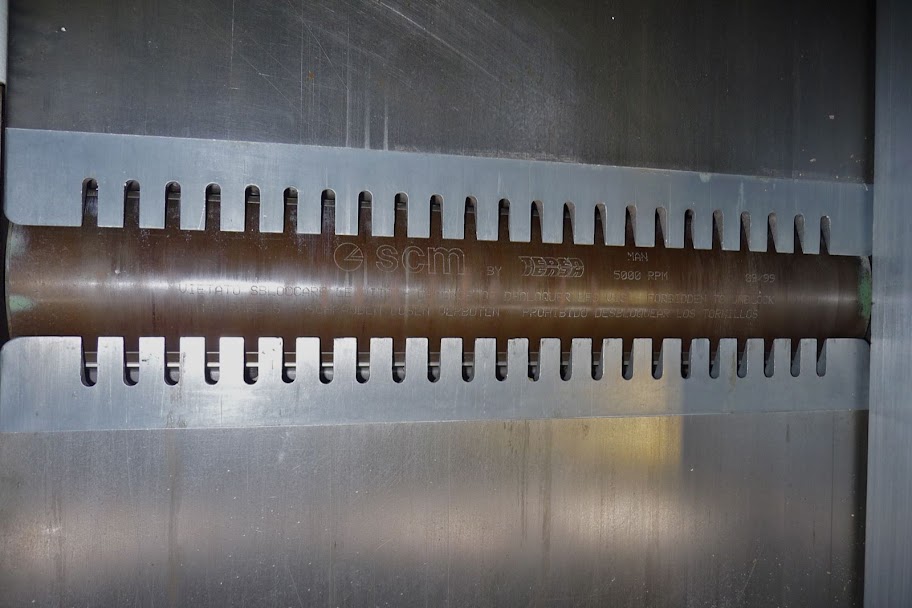

OK, here are some pics of the cluttered shop. The jointer is not optimally located yet. I will have to re-arrange things if I get some slow time. Mostly, we use it for touching up edges on batches of panel staves, so the short outfeed clearance is not a big deal, usually. I will clean up the head really well as soon as I can. Maybe get some SCM white paint and a new decal...

JR

Now THAT'S what I'm talking about! Congrats on gettin' that monster. I'm TOTALLY jealous of your space...

I drink, therefore I am.

Excellent!

You looked under the hood. Is the motor on that unit proprietary or could it be substituted with something else with a little work.

Reason I ask is I am trying to make a deal on an older F410, must be about 15-20 years old as it has the same two green colors as my shaper, but the running condition is unknown. Would make a difference on what I would pay as I have a new heavy 5 hp Baldor 3ph sitting on the shelf.

I had to buy a motor for my minimax slider that is a proprietary design, and it hurt a bit.

On the Tersa knives/head I clean mine every time I put in new blades, and I clean the opposite side of the blade when I flip them. I have never had a problem since new with this small bit of maintainance. I don't use oil because I don't want oil on my wood, I just spray it with TopCote every time I use it. If I plane a lot of pine I clean it immediately with lacquer thinner, a brass brush, and an air gun. Works for me.

Definately makes your shop look better...

Larry

Larry, wouldn't you be better off just to have the motor rewound? $300-400 and back to as good as new, and easier to resell. J R great pictures and it looks like the important stuff is in good shape. Dave

Yes Larry, but I meant to rewind the jointer motor rather than substitute the Baldor. You are correct that the swap is probably fairly easy though. Seems like there are no easy alternatives to the Euro parts so the companies kind of gouge you. Dave

I will have to take another look. On all of the SCM stuff that I have, the motor mount has a decent adjustment range, so I would think that worst case would be a sub plate for the motor mounting and a pulley of the proper diameter to fit the shaft on the Baldor. SCM usually does nice pulley setups, with tapered mounts for centering. I bet the original motor is fine though...

JR

You call that cluttered? Man I'd love to be able to see that much of my floors

JeffD