I've just a acquired a maebiki-nokogiri from Japan. It's in good shape, just missing the handle. I got Odate's book "Japanese Woodworking Tools" and read through the saw section. I've also watched all the videos I can find on YouTube.

I sharpened it and tried it out on short sections of green applewood and eastern cedar by wrapping the handle tang in cloth. It works ok for a bit, then binds horribly. I've secured the logs in the leg vise of my Roubo bench, and I'm just dragging the bench around trying to cut.

Does anyone have any experience using these to help me figure out what I'm doing wrong? I posted to the Japanese Woodworking Forum at http://www.shizutanischool.org/phpBB...81f4edb82a9a8d, but have only gotten one reply.

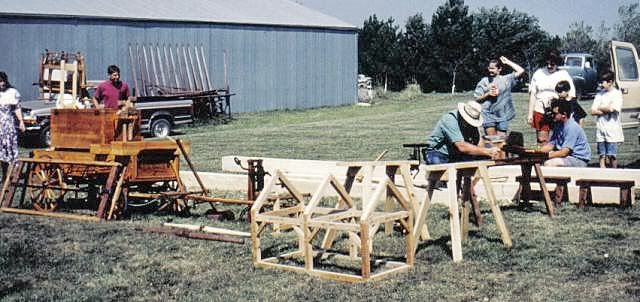

Here's a picture of it:

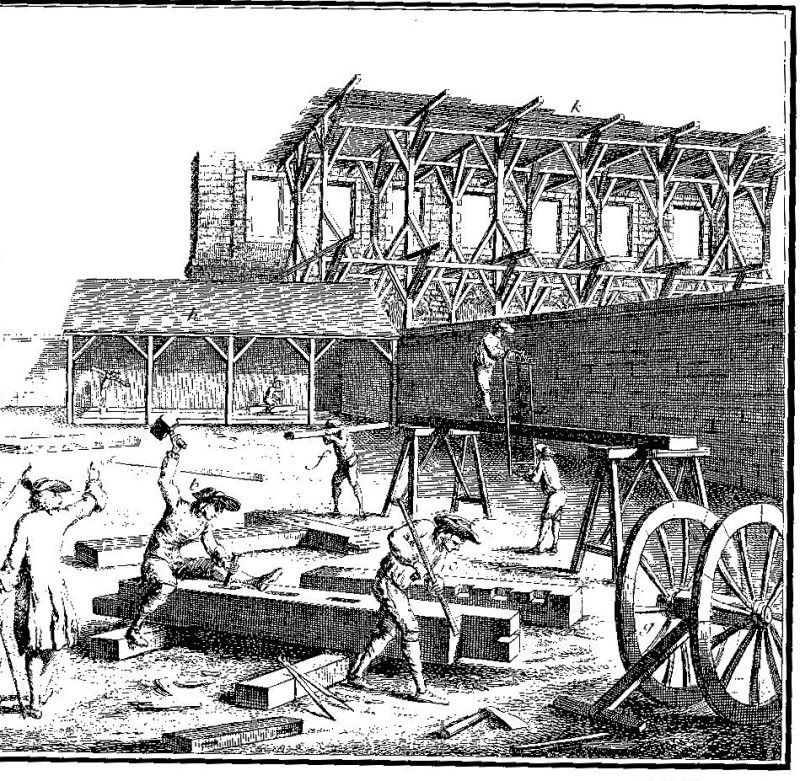

And Harry, any hints on building one of those large frame saws? What did you use for the blade?

Last edited by Steve Branam; 05-20-2010 at 8:09 AM.

Steve, mostly hand tools. Click on my name above and click on "Visit Homepage" to see my woodworking blog.

Reply With Quote

Reply With Quote

Jr.

Jr.