As the title says, I am seeking info on Hot Rodding (getting the most of) my Delta 50-850 Type 2 dust collector. I mostly work with MDF in my shop. I do custom upholstery, mostly in older classic cars and hot rods. I use a lot of MDF and luan in my projects. I have been putting together the wood working part of my shop this year. I have a 1973 Unisaw that I have set up for my needs. The Unisaw and a router mounted in a Bench Dog cast iron extension wing are my only real dust producers right now.

What I currently have:Delta 50-850 Type 2. I removed the Y at the inlet. It has the Delta canister filter on it.

6" PVC S&D main header connected directly to the inlet.

4" PVC S&D to the Unisaw base and under-table router box.

4" PVC S&D to a short (~30") 4" hose to either the saw's Shark Guard w/4" port or the router fence dust port with 2.25 -> 4" adapter.Jet AFS-1000B air filter with Jet filters.

Things I'm considering doing:Removing the steel 4" baffle on the inlet to the impeller.

Making a Phil Thien design baffle.

Replacing the cartridge with a Wynn Environmental Nanofiber .5 micron cartridge.

Installing Wynn Environmental filter and bag in the Jet air filter.

Goals:I don't want to spend a bunch of money for little return. ie: most bang for the buck, taking in to account what I already own.

Capture as much dust at the source as I can, of course

Get the most out of the 50-850.

Do it right the first time so I'm not ripping it all out in a few months to change it up.

I have spent many hours reading everything I can find on the subject, which is how I have got the info above. I welcome any input, advice, photos, links, etc.

Thanks!

Steven

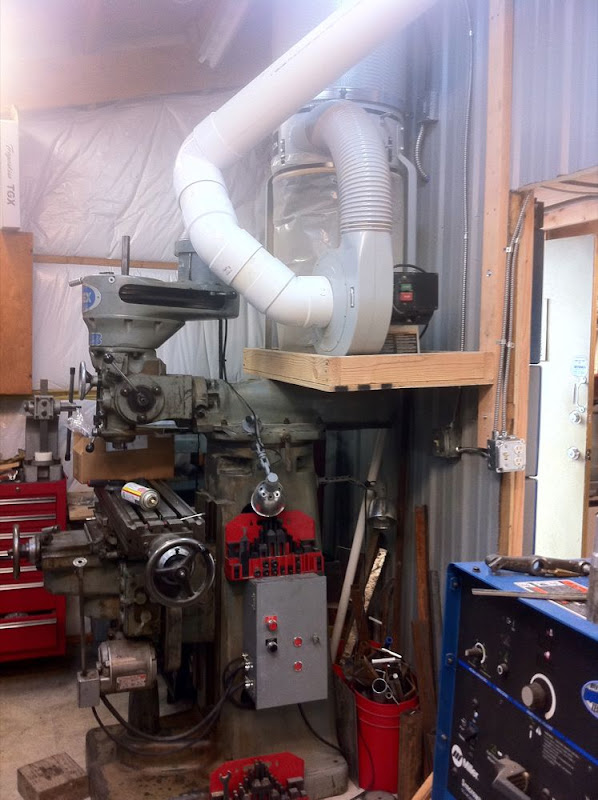

Some photos..

Yes, my dust collector is sitting on my milling machine..

The light by the canister will be moved..

I couldn't find a local supplier for 6" wye so I used a tee.

The lower 4" connections.

Reply With Quote

Reply With Quote